In the realm of interior design and architectural finishes, surfaces play a pivotal role in defining the aesthetic and functional essence of a space. For decades, natural stone, particularly marble, has been lauded for its timeless elegance and luxurious appeal. However, the quest for materials that offer comparable beauty with enhanced practicality and cost-effectiveness has led to the rise of a compelling alternative: artificial marble. Often referred to as engineered stone or solid surface, this manufactured material has carved out a significant niche, gracing countertops, vanities, flooring, and decorative elements across a spectrum of residential and commercial projects. But what exactly is artificial marble, and what are its defining characteristics that have propelled it into the spotlight?

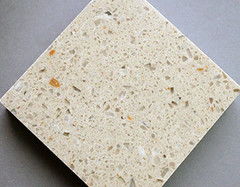

At its core, artificial marble is a composite material meticulously crafted to mimic the visual splendor of natural marble. Unlike its geological counterpart, which is quarried from the earth, artificial marble is produced through a sophisticated manufacturing process. The most prevalent forms include quartz surfaces and solid surface materials, each with its own unique composition and manufacturing technique. Quartz surfaces, for instance, are predominantly made from ground natural quartz crystals, bound together with polymers and pigments. This high concentration of quartz, typically around 90-95%, imbues these surfaces with exceptional hardness and durability. The polymers act as a binder, ensuring the integrity of the slab, while pigments are introduced to replicate the intricate veining, color variations, and overall visual depth characteristic of natural marble.

Solid surface materials, on the other hand, often consist of acrylic or polyester resins combined with mineral fillers, such as bauxite or alumina trihydrate. This formulation allows for a greater degree of flexibility in design and fabrication. The resins provide a non-porous, seamless finish, while the mineral fillers contribute to its structural integrity and fire resistance. The manufacturing process for solid surfaces typically involves casting these components into sheets or shapes, which can then be thermoformed and seamlessly joined, creating a continuous, unblemished surface.

The appeal of artificial marble lies not only in its ability to replicate the beauty of natural stone but also in the significant advantages it offers in terms of performance and maintenance. One of the most striking benefits is its durability. Quartz surfaces, due to their high quartz content, are incredibly hard and resistant to scratches, chips, and cracks. This makes them an ideal choice for high-traffic areas like kitchen countertops, where they can withstand the rigors of daily use without showing significant wear and tear. Similarly, solid surfaces, while not as hard as quartz, are impact-resistant and can be repaired relatively easily if damaged, often by sanding out scratches or filling in chips.

Another key advantage is the non-porous nature of most artificial marble materials, particularly quartz surfaces and many solid surface formulations. Natural marble, by contrast, is inherently porous, meaning it can absorb liquids, stains, and bacteria if not properly sealed. This porosity can lead to unsightly blemishes and pose hygienic concerns. Artificial marble, with its tightly bound structure, resists the penetration of liquids, making it highly stain-resistant. Spills of wine, coffee, or oil can typically be wiped away with ease, preserving the pristine appearance of the surface. This characteristic also contributes to its hygienic properties, as it does not provide a breeding ground for bacteria or mold.

Consistency and uniformity are further hallmarks of artificial marble. While the beauty of natural stone lies in its unique, often unpredictable patterns, this very variability can sometimes be a disadvantage, especially when large, uniform surfaces are desired or when matching slabs for a project becomes a challenge. Artificial marble, produced under controlled factory conditions, offers a predictable and consistent appearance. The veining, color, and pattern are deliberately engineered, allowing designers and homeowners to achieve a specific look with confidence, knowing that each slab or piece will closely resemble the approved sample. This consistency simplifies planning and execution in construction and renovation projects.

The versatility in design is another compelling factor. The manufacturing process allows for an almost limitless palette of colors and patterns. Beyond mimicking natural marble, artificial marble can be created in solid colors, vibrant hues, or even unique, custom designs that are impossible to find in nature. This opens up a world of creative possibilities, enabling designers to tailor surfaces to specific interior schemes or to make bold design statements. Furthermore, the ability to thermoform solid surfaces into curved shapes or to create seamless joints allows for the design of intricate and fluid architectural elements that would be challenging or impossible with natural stone.

Finally, cost-effectiveness often plays a significant role in the decision-making process. While high-end artificial marble options can command a premium price, they are generally more affordable than comparable natural marble slabs, especially when considering the overall cost of fabrication, installation, and ongoing maintenance. The reduced need for frequent sealing and the enhanced durability can lead to lower lifetime costs, making artificial marble a smart investment for many.

In summary, the initial part of our exploration into artificial marble highlights its engineered nature, focusing on its composition, manufacturing processes, and the primary benefits it brings to the table: exceptional durability, non-porous and hygienic surfaces, design consistency, remarkable aesthetic versatility, and a favorable cost-performance ratio. These attributes collectively position artificial marble as a modern, practical, and aesthetically pleasing alternative to traditional natural stone.

While artificial marble undoubtedly offers a compelling array of advantages, a comprehensive understanding necessitates an equally thorough examination of its potential drawbacks and specific characteristics that distinguish it from its natural counterpart. Recognizing these nuances is crucial for making informed decisions that align with both aesthetic aspirations and practical requirements.

One of the primary considerations when evaluating artificial marble is its origin and composition. Although designed to mimic natural marble, it is fundamentally a manufactured product. This can be a point of contention for purists who value the inherent uniqueness and organic origins of natural stone. The “soul” or natural variation found in quarried marble, with its geological history etched into its veining and patterns, is absent in an engineered material. While artificial marble excels in consistency, it can sometimes lack the inimitable character and depth that only nature can provide. Some individuals may find the engineered patterns to be repetitive or less dynamic compared to the intricate, naturally formed designs of marble.

Another aspect to consider is its resistance to heat. While quartz surfaces offer good heat resistance, they are not entirely impervious to extreme temperatures. Placing very hot pots or pans directly onto a quartz countertop can potentially cause thermal shock, leading to discoloration or even cracking. It is advisable to use trivets or heat pads to protect the surface from prolonged exposure to high heat. Solid surfaces, particularly those based on resins, tend to have lower heat resistance than quartz and can soften or warp under intense heat. This makes them less ideal for direct cooking applications where hot pans are frequently used. Natural marble, while also susceptible to thermal shock and etching, often possesses a higher tolerance for heat in some of its denser varieties.

The environmental impact of artificial marble is also a subject of discussion. The manufacturing process involves energy-intensive procedures and the use of resins and chemicals. While many manufacturers are increasingly focusing on sustainable practices and recycled content, the production of engineered materials inherently has a different environmental footprint than simply quarrying and shaping natural stone. The extraction of raw materials for the fillers and the production of polymers contribute to this. However, the longevity and durability of artificial marble can lead to fewer replacements over time, potentially offsetting some initial environmental concerns. The recyclability of some artificial marble products is also improving.

Repairability can be a mixed bag depending on the type of artificial marble. As mentioned, solid surfaces can often be repaired relatively seamlessly. However, deep scratches or chips in quartz surfaces can be more challenging to fix invisibly, and while they are highly durable, they are not indestructible. In cases of significant damage, replacement of the affected section or the entire slab might be necessary, which can be costly. Natural marble, while prone to etching and staining, can often be professionally restored, polished, and sealed to revive its appearance.

The appearance and feel of artificial marble, while impressive, can sometimes differ subtly from natural stone. While advancements in technology have made the replication of veining and texture remarkably sophisticated, a discerning eye might detect a certain artificiality. The “feel” of the surface, the way it reflects light, or the subtle nuances in its texture might not perfectly mirror the natural variations and tactile experience of quarried marble. This is often a subjective preference, but it is a factor that some designers and homeowners consider.

Furthermore, the cost of high-end artificial marble can be substantial. While generally more affordable than premium natural marbles, the most sophisticated engineered stones with complex veining and unique color patterns can rival or even exceed the price of mid-range natural marble. This means that affordability is relative and depends heavily on the specific product chosen.

In conclusion, while artificial marble stands out for its durability, low maintenance, design flexibility, and often favorable cost, its limitations regarding extreme heat, potential environmental considerations in manufacturing, the absence of natural geological character, and the subtle differences in feel and appearance warrant careful consideration. The decision between artificial and natural marble, or indeed other surfacing materials, ultimately hinges on a detailed assessment of priorities. For those seeking a highly practical, consistently beautiful, and resilient surface that can withstand the demands of modern living, artificial marble offers an exceptional solution. However, for those who prioritize the unique, unrepeatable artistry of nature and are prepared for the associated maintenance and cost, natural marble retains its unparalleled allure. Artificial marble is not merely a substitute; it is a distinct category of material, offering its own set of unique characteristics and benefits that have rightfully earned it a prominent place in the world of design.