Part 1: Outline

Outline: Are Artificial Marble Countertops Toxic?

Introduction

What is artificial marble?

Why people worry about safety

Materials and Composition

Cultured marble basics

Resin matrices used

Crystalline fillers and pigments

Engineered quartz basics

Quartz aggregate

Resin binders (epoxy/polyester)

Health and Toxicity Considerations

During manufacturing and fabrication

VOC emissions and curing

Dust exposure and crystalline silica

During use and maintenance

Touch safety and chemical exposure

Stains, heat, and cleaning agents

Safety Practices and Recommendations

When installing

At home maintenance

DIY vs professional work

Regulatory and Safety Guidance

Safety data sheets (SDS)

Workplace and consumer safety standards

Alternatives and Comparisons

Quartz vs cultured marble for toxicity

Other non-toxic countertop options

Common Myths

Myth: All resins are dangerous

Myth: They release toxins in kitchen use

Conclusion

FAQ

Q1: Are artificial marble countertops safe to touch?

Q2: Is cutting on cultured marble dangerous?

Q3: Do these countertops off-gas VOCs after installation?

Q4: How should I dispose of damaged countertops?

Q5: What precautions should I take when drilling or grinding?

Part 2: Article

Are Artificial Marble Countertops Toxic? 人造大理石台面有毒吗?

Introduction

When people ask whether “artificial marble” countertops are toxic, they’re really wondering about two broad categories: cultured marble (a resin-bound stone alternative) and engineered quartz (crystal-rich slabs bound with resin). Both are popular in kitchens and bathrooms, prized for consistency, stain resistance, and low porosity. But like any manufactured material, they come with safety notes. This article unpacks what these countertops are made of, what toxicity risks, if any, exist, and practical steps to keep your home safe—without unnecessary alarm.

What Is Artificial Marble?

Artificial marble is a blanket term for man-made surfaces designed to resemble natural marble. It mainly includes two types:

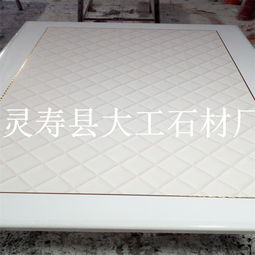

Cultured Marble

Cultured marble is created by combining crushed marble with a polyester or acrylic resin, then pouring the mixture into molds. It often has built-in sinks and seamless edges. The finished product is easier to shape and generally more uniform in color and pattern than natural stone.

Resin Matrices Used

The resin acts as a binder and gives the slab its structural integrity. Common binders include polyester and acrylic (and sometimes epoxy in higher-end formulations). The resin holds the stone particles together, creates a smooth surface, and determines some chemical resistance properties.

Crystalline Fillers and Pigments

Ground marble or other fillers provide the “stone” look, while pigments provide color. These components stay locked inside the resin once cured, contributing to the surface’s aesthetics and durability.

Engineered Quartz

Engineered quartz countertops aren’t marble at all; they’re mostly quartz crystals bound with polymer resins. The result is an extremely hard, non-porous surface with high scratch and heat resistance, valued in busy kitchens.

Quartz Aggregate

Quartz crystals make up a large portion of the material. The silica content gives strength and durability, which is why these slabs are so popular for long-wearing counters.

Resin Binders (Epoxy/Polyester)

The resin binds the quartz together. Epoxy and polyester resins are common, with epoxy typically offering strong chemical resistance and durability, while polyester can be more cost-effective. Curing this resin creates a solid, seamless surface.

Health and Toxicity Considerations

Here’s what to know about toxicity in real-world use.

During Manufacturing and Fabrication

- VOC Emissions: Some resins release volatile organic compounds (VOCs) as they cure. Proper ventilation and, in professional shops, exhaust systems help minimize exposure. Once cured, VOCs drop dramatically.

- Dust Exposure: Cutting or grinding engineered stone and cultured marble generates dust. The dust from quartz-containing materials can include crystalline silica, which is hazardous if inhaled in fine form.

During Use and Maintenance

- Touch Safety: For most people, simply touching or cooking on cultured marble or engineered quartz is not hazardous. The finished surface is non-porous and inert after curing, so contact with the surface is generally safe.

- Stains, Heat, and Cleaning Agents: Harsh chemicals, strong alkalis or acids can degrade resin surfaces over time, potentially leading to micro-abrasions that harbor contaminants or affect surface integrity. Bleach and strong solvents can also affect some resin types if used improperly.

Safety Practices and Recommendations

Practical steps can reduce risk without making countertop care overly complicated.

When Installing

- Use professionals for cutting and fabrication when possible. This minimizes the amount of silica dust and ensures proper waste containment.

- Ventilation is key during installation to reduce VOC exposure from curing resins.

At Home Maintenance

- Clean with pH-neutral cleaners or cleaners recommended by the manufacturer.

- Avoid abrasive tools that scratch the surface; use cutting boards and trivets.

- Don’t use the countertop as a hot plate—extreme heat can damage resin and compromise the surface.

DIY vs Professional Work

- DIY cutting, drilling, or grinding increases exposure to silica dust and off-gassing during cure. If you take on any fabrication or modifications, wear a suitable respirator (not just a dust mask), eye protection, and ensure good ventilation.

Regulatory and Safety Guidance

- Safety Data Sheets (SDS): Always check the SDS for the specific product you’re using. It provides details on hazard classifications, handling, and first-aid measures.

- Standards and Guidelines: Workplace safety standards (like those governing silica dust) apply during fabrication. For consumer use, follow manufacturer recommendations and local regulations regarding ventilation and handling.

Alternatives and Comparisons

- Quartz vs Cultured Marble: Quartz countertops usually have higher scratch resistance and non-porous surfaces, but both can be engineered with safe binders when installed and maintained correctly. Cultured marble might be more prone to staining and chemical etching because of its resin matrix.

- Other Non-Toxic Options: Solid-surface materials (e.g., acrylic solid-surface sheets), glass, and certain natural stones with proper sealing can be alternatives, each with its own safety and maintenance profiles.

Common Myths

- Myth: All resins are dangerous. Reality: Most resins are inert once fully cured. The risk is primarily during manufacturing, curing, and fabrication when exposure to unreacted components or dust can occur.

- Myth: They release toxins when used in kitchens. Reality: In normal kitchen use, cured countertops are generally safe. Off-gassing is most relevant during curing and installation, not during daily use.

Conclusion

Artificial marble countertops—whether cultured marble or engineered quartz—are designed for everyday use in homes and offices. The main toxicity considerations are connected to fabrication and installation (dust and VOCs during curing) and to long-term maintenance (protecting the resin binder from harsh cleaners and extreme heat). With proper precautions—professional fabrication, adequate ventilation, PPE during cutting, and careful maintenance—these materials can be safe and durable parts of a kitchen or bathroom. The key is to know the specific product you’re using, follow the manufacturer’s guidance, and minimize exposure during any cutting or drilling work.

FAQ

1) Q: Are artificial marble countertops safe to touch?

A: For everyday contact and use, yes. Once fully cured, both cultured marble and engineered quartz are considered non-toxic for typical handling and cooking activities.

2) Q: Is cutting on cultured marble dangerous?

A: Cutting on any countertop without a cutting board increases the risk of scratching and releasing fine particles during fabrication. If you must cut, use a protective barrier and a dust mask to limit exposure to any dust.

3) Q: Do these countertops off-gas VOCs after installation?

A: VOC off-gassing is most relevant during the curing stage of the resin. After the material has fully cured in a normal environment, VOC emissions are typically negligible.

4) Q: How should I dispose of damaged countertops?

A: Follow local waste guidelines. If the material contains hazardous primer components or coatings, contact your local waste management authority. For minor scrapes or repairs, consult the manufacturer’s repair instructions.

5) Q: What precautions should I take when drilling or grinding?

A: Wear a suitable respirator (not just a simple dust mask), eye protection, and gloves; use water suppression to minimize dust; ensure adequate ventilation; and dispose of dust properly to avoid inhalation of fine silica particles.