The whisper of luxury, the cool touch of timeless elegance – these are the sensations that often come to mind when we think of marble. For centuries, this natural stone has graced the halls of palaces, adorned the sculptures of masters, and lent an air of unparalleled sophistication to spaces. Yet, the very qualities that make natural marble so coveted – its exquisite veining, its unique formations, its sheer, breathtaking beauty – also present challenges. Scarcity, the potential for porosity and staining, and the significant weight can all be limiting factors in modern design and construction. Enter artificial marble, a material that has, in recent decades, emerged as a captivating contender, offering a harmonious marriage of aesthetic appeal and cutting-edge material science.

But what exactly is artificial marble? The term itself conjures images of synthetic imitations, perhaps lacking the soul and authenticity of its natural counterpart. However, to dismiss it as merely a “fake” would be to overlook a remarkable innovation. Artificial marble, more accurately termed composite stone or engineered stone, is a meticulously crafted material that leverages the beauty of natural elements with the resilience and versatility of modern polymers. It’s not a single, monolithic substance, but rather a family of materials, each with its own unique recipe and characteristics, all united by the common goal of recreating and often enhancing the desirable qualities of natural marble.

At its core, artificial marble is typically composed of a blend of natural mineral fillers and binding agents, most commonly polymer resins. Think of it as a sophisticated composite, where finely ground natural materials are suspended and bound together by a matrix that provides strength, uniformity, and a specific aesthetic. The most prevalent types of artificial marble utilize either polyester or acrylic resins as the binder. Polyester resins, known for their excellent workability and cost-effectiveness, often form the backbone of many solid surface materials that mimic marble. Acrylic resins, on the other hand, offer superior UV resistance and a clearer, more luminous quality, making them ideal for applications where light plays a significant role.

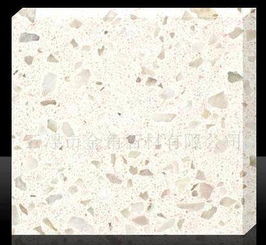

The mineral fillers are where much of the visual magic happens. These can include a variety of natural substances, with ground quartz and calcium carbonate being among the most common. Quartz, a hard and abundant mineral, contributes significantly to the durability and scratch resistance of the composite. The finely ground particles of quartz, when strategically distributed, can create a subtly granular texture and an underlying depth that mimics the inherent character of natural stone. Calcium carbonate, often derived from limestone or chalk, can provide a brighter white base and a smoother finish. The precise ratio and particle size of these fillers are crucial, as they dictate the final appearance, texture, and physical properties of the artificial marble.

Beyond the basic resin and mineral filler combination, manufacturers employ a spectrum of techniques to achieve the diverse and intricate patterns that define artificial marble. Pigments are, of course, essential. These are carefully selected and blended to replicate the iconic veining, swirls, and mottling found in natural marble. Sophisticated color-matching technologies ensure consistency, allowing designers to specify precise shades and patterns with confidence. Furthermore, the process of creating the “veins” is an art form in itself. This can be achieved through various methods, such as injecting different colored resins into the mixture, using dyes that bleed and diffuse to create organic-looking patterns, or employing advanced digital printing techniques to lay down intricate designs with remarkable fidelity. The result is a surface that can range from subtle, almost ethereal marbling to bold, dramatic statements that rival the most prized natural quarries.

The creation of artificial marble is a testament to the ingenuity of material science. The process often begins with the preparation of the raw ingredients – the resins, fillers, and pigments are meticulously measured and mixed to achieve the desired composition. This slurry is then poured into molds, often on large casting tables or in specialized machinery. For solid surface materials, the mixture is typically spread thinly and evenly, allowing it to cure and solidify. For materials that aim to replicate the thickness and substantial feel of natural stone slabs, thicker molds are used, and the curing process is carefully controlled to ensure optimal strength and integrity. During the curing phase, the resins undergo a chemical reaction, hardening and binding the mineral fillers into a solid, cohesive material. Once cured, the material is then cut, polished, and finished to meet the specific requirements of its intended application. This controlled manufacturing process is precisely what allows for the remarkable consistency, uniformity, and predictable performance that artificial marble offers. It’s a departure from the often unpredictable nature of geological formations, offering designers and builders a level of reliability and customization that natural stone, by its very definition, cannot always provide.

The allure of artificial marble extends far beyond its fascinating composition; it lies in the tangible advantages it brings to the table, transforming spaces and empowering creative vision. One of the most compelling aspects is its inherent durability and low maintenance. Unlike many natural marbles, which can be porous and susceptible to staining from acids, oils, and colored liquids, the resinous nature of artificial marble creates a non-porous surface. This makes it exceptionally resistant to stains, moisture, and bacteria. Spills of wine, coffee, or even harsh cleaning agents are less likely to penetrate and leave unsightly marks, greatly simplifying upkeep. A quick wipe with a damp cloth and mild soap is often all that’s needed to keep surfaces looking pristine. This ease of care is a significant boon for busy households, high-traffic commercial spaces, and environments where hygiene is paramount, such as kitchens and bathrooms.

Furthermore, the non-porous quality translates to improved hygiene. Natural stone, with its microscopic pores, can harbor bacteria and mold, making it a less ideal choice for certain sensitive environments. Artificial marble, by sealing out these unwanted guests, provides a cleaner and healthier surface. This is a critical consideration for designers of healthcare facilities, restaurants, and any space where public health is a priority. The uniform composition also means that artificial marble is less prone to cracking or chipping compared to some natural stones, especially in areas subject to impact or thermal shock. While it’s not indestructible, its engineered resilience offers a greater degree of confidence in its long-term performance.

The aesthetic versatility of artificial marble is another significant draw. The ability to precisely control color, pattern, and finish opens up a world of design possibilities that often surpass the limitations of natural stone. Designers are not confined to the veining patterns found in a specific quarry; they can create custom looks tailored to any aesthetic. Want a dramatic, deep black with stark white veins that mimic Calacatta but with a specific width and flow? Artificial marble can deliver. Perhaps a soft, ethereal pastel with subtle shimmer? That too, is within reach. This level of customization allows for a truly bespoke approach to interior design, enabling architects and homeowners to achieve a cohesive and personalized vision without compromise. The consistent color and pattern also mean that if a piece is damaged, a replacement section can be fabricated to match seamlessly, a feat that can be challenging with unique natural stone slabs.

Weight is another practical consideration where artificial marble often shines. Natural marble, particularly in slab form, is incredibly heavy, requiring reinforced structures and specialized handling during installation. Artificial marble, especially solid surface varieties, can be significantly lighter, making it easier to transport, handle, and install. This can lead to cost savings in terms of labor and structural requirements, making ambitious design ideas more feasible and accessible. While some engineered quartz products can still be quite substantial, they generally offer a more manageable weight profile than their natural counterparts of equivalent thickness.

The environmental aspect is also becoming increasingly important in material selection, and artificial marble presents a compelling case. By utilizing recycled materials and minimizing waste during the manufacturing process, many artificial marble products offer a more sustainable option. The use of natural mineral fillers, often sourced locally or responsibly, can also reduce the carbon footprint associated with mining and transportation. Furthermore, the durability and longevity of artificial marble mean that it doesn’t need to be replaced as frequently as less robust materials, contributing to a more sustainable lifecycle. While the production of resins does involve chemical processes, ongoing advancements in material science are leading to the development of more eco-friendly binders and manufacturing techniques.

From sleek, modern kitchen countertops that resist stains and spills with effortless grace, to expansive, seamless bathroom vanities that evoke a sense of spa-like tranquility, artificial marble has found its place in virtually every corner of the modern home. Its applications extend to wall cladding, shower surrounds, flooring, furniture surfaces, and even decorative architectural elements. In commercial settings, it graces reception desks, bar tops, retail displays, and hospitality interiors, offering a durable and visually stunning solution. The ability to create large, seamless panels without grout lines further enhances its appeal in areas demanding both hygiene and a clean aesthetic. The technology has advanced to a point where the tactile experience and visual depth of artificial marble can be remarkably convincing, often fooling the untrained eye. It offers a bridge between the aspirational beauty of natural stone and the practical demands of contemporary living, proving that innovation can indeed enhance, rather than diminish, the timeless allure of elegance.