The world of interior design and home renovation often presents us with a dazzling array of material choices. From the gleaming allure of quartz to the rustic charm of wood, each material promises a unique aesthetic and functional profile. Among the contenders vying for a spot in our kitchens, bathrooms, and decorative spaces, two often come up in conversation: acrylic and solid surface. While they share some similarities and are sometimes conflated, understanding their distinct characteristics is paramount to selecting the right material for your needs. This article will delve deep into the world of acrylic and solid surface, unraveling their advantages and disadvantages to equip you with the knowledge to make a confident choice.

Let’s begin with acrylic. Often recognized by brand names like Corian (though Corian is technically a brand of solid surface, the name has become somewhat generalized in popular discourse), acrylic, or more precisely, solid acrylic surfaces, are a type of non-porous, man-made material. They are composed primarily of acrylic polymers and alumina trihydrate (ATH), derived from bauxite ore. This composition gives acrylic its characteristic properties: it’s workable, repairable, and can be thermoformed into various shapes.

One of the most significant advantages of acrylic is its sheer versatility. Its ability to be heated and molded means that designers and fabricators can create seamless, flowing designs that are difficult to achieve with other materials. Imagine a kitchen island with an integrated sink, where the countertop and sink appear to be one continuous piece, with no visible seams. This seamlessness not only offers a sleek, modern aesthetic but also contributes to its hygienic properties, as there are no crevices for dirt and bacteria to accumulate. This makes acrylic an excellent choice for healthcare settings and food preparation areas where sanitation is a top priority.

Furthermore, acrylic is remarkably durable and resistant to stains. Its non-porous nature means that liquids like wine, coffee, or oil will not penetrate the surface, making cleanup a breeze. Minor scratches or scuffs, which can be a concern with many countertop materials, can often be buffed out or repaired relatively easily, sometimes even by the homeowner with a fine-grit sandpaper and a polishing compound. This repairability adds to its long-term value and appeal.

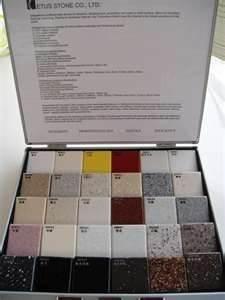

The color palette for acrylic is vast and diverse. It can be manufactured in a wide spectrum of colors, patterns, and even translucent options, allowing for a high degree of customization. This means you can achieve a look that perfectly complements your existing décor or embark on a bold new design direction. Its lightweight nature also makes it easier to transport and install compared to heavier stone materials, potentially reducing installation costs.

However, like any material, acrylic is not without its drawbacks. While it’s durable, it’s not impervious to damage. Its relatively softer nature means it can be more susceptible to scratching from sharp objects or abrasive cleaning materials compared to harder surfaces like granite or quartz. While repairs are possible, significant damage, such as deep gouges or burns, might require professional intervention and can be more costly than simply cleaning the surface.

Heat resistance is another area where acrylic can be a concern. While it can withstand moderate heat, placing extremely hot pots or pans directly on the surface can cause discoloration or even melting. Therefore, the use of trivets and hot pads is strongly recommended, a practice that is good advice for most countertop materials anyway, but perhaps more critical with acrylic.

The cost of acrylic can also be a consideration. While it can be more affordable than some high-end natural stones or engineered quartz, it often comes with a higher price tag than laminate or some other composite materials. The specialized fabrication techniques required for its seamless integration and thermoforming can also contribute to its overall cost.

Now, let’s pivot to solid surface. This is where some of the confusion often arises because “solid surface” is a broad category, and acrylic is a type of solid surface. However, when people differentiate “acrylic” from “solid surface,” they are often referring to the difference between 100% acrylic solid surface and composite solid surface materials. Composite solid surfaces typically contain a significant amount of acrylic resin binder along with mineral fillers, often ATH, and sometimes other additives. The exact composition can vary between manufacturers.

The advantages of solid surface materials are remarkably similar to those of acrylic, primarily because of the shared components. They are non-porous, meaning they resist stains and bacteria growth, making them highly hygienic. This is a major selling point for both kitchen and bathroom applications, as well as commercial settings. The seamless installation is also a hallmark of solid surface, allowing for integrated sinks, backsplashes, and complex edge details without visible grout lines or seams. This contributes to a clean, modern aesthetic and simplifies cleaning and maintenance.

Repairability is another key strength. Minor scratches and scuffs can often be sanded out, restoring the surface to its original appearance. This makes solid surface a durable and long-lasting option, especially when compared to materials that are more prone to permanent damage.

The aesthetic possibilities with solid surface are also extensive. They come in a vast array of colors, patterns, and textures, mimicking the look of natural stone, granite, or even offering unique abstract designs. The ability to be thermoformed into curved shapes also allows for a great deal of design freedom, enabling custom creations for a variety of applications, from reception desks to intricate architectural features.

However, the distinction between acrylic solid surfaces and other composite solid surfaces can sometimes lie in their performance characteristics. While generally durable, some composite solid surfaces might be slightly more prone to scratching than 100% acrylic versions, depending on the specific formulation. This is not a universal rule, and high-quality composite solid surfaces can be very resilient.

The heat resistance of composite solid surfaces is also comparable to acrylic – good, but not excellent. Direct contact with very hot items can cause damage, and the use of heat-resistant mats and trivets is always recommended. While repairable, deep heat damage can be more challenging to fix perfectly than minor scratches.

Cost-wise, solid surface materials generally fall into a mid-to-high price range, often competitive with engineered quartz but generally less expensive than high-end natural stones like granite or marble. The price can fluctuate based on the brand, complexity of the design, and the specific color and pattern chosen.

The key takeaway from part one is that both acrylic and solid surface materials offer a compelling blend of aesthetics, hygiene, and practicality. They excel in creating seamless, modern designs and are a strong choice for areas where cleanliness is paramount. However, their susceptibility to scratches and heat damage, compared to harder materials like quartz, is a crucial factor to consider. The nuances between 100% acrylic solid surfaces and other composite solid surfaces can sometimes influence their performance and cost, making it important to understand the specific product you are considering.

Continuing our exploration into the world of acrylic and solid surface materials, we’ve established that both offer a fantastic blend of form and function. However, to truly make an informed decision, we need to delve deeper into the practicalities of their differences and how these might impact your specific project. Let’s focus on the everyday use and long-term implications of choosing acrylic versus solid surface.

When we talk about the “feel” of a material, it can be quite subjective, but it’s an important aspect of a material’s appeal. Acrylic solid surfaces often have a slightly warmer, more “plastic-like” feel compared to some composite solid surfaces. This is due to their higher acrylic polymer content. While not necessarily a negative, some individuals prefer the more mineral-like, sometimes cooler touch of composite solid surfaces, which can more closely mimic the feel of natural stone. This is, of course, a matter of personal preference and can be easily assessed by touching samples of both materials.

The translucency factor is another area where acrylic often shines, especially for design applications beyond basic countertops. Many acrylic solid surfaces can be backlit, creating a stunning luminous effect. This opens up a world of design possibilities for feature walls, illuminated bars, or decorative panels. While some composite solid surfaces can offer a degree of translucency, it’s generally more pronounced and easier to achieve with 100% acrylic formulations. If you’re envisioning a design that incorporates subtle lighting effects, acrylic might be the more suitable choice.

When it comes to fabrication, both materials require specialized tools and techniques. However, acrylic’s inherent flexibility when heated makes it particularly amenable to intricate curves, seamless joints, and complex shapes. This means that if your design involves a lot of organic curves or custom-molded elements, an acrylic solid surface might offer more design freedom and potentially a more cost-effective fabrication process for those specific features. Composite solid surfaces can also be thermoformed, but the achievable radii and complexity might be slightly more limited depending on the exact composition and manufacturer.

The long-term maintenance and repair are where the nuances become even more critical. As mentioned, minor scratches on both materials can often be repaired. For acrylic, a light sanding followed by polishing can often remove superficial scratches. However, if the scratch is deeper, more aggressive sanding might be required, and achieving a perfect match in sheen can sometimes be a challenge, especially on darker or highly patterned surfaces. Professional refinishing is often the best route for significant damage to ensure a seamless repair.

For composite solid surfaces, the repair process is similar – sanding and polishing. However, the presence of different mineral fillers and binders can sometimes mean that the color or pattern might not perfectly match after a repair, especially if the surface has aged or been exposed to UV light differently across its lifespan. Again, professional expertise can often mitigate these issues. It’s worth noting that many manufacturers offer specific repair kits and instructions for their products, which can be very helpful for minor touch-ups.

Environmental considerations are also becoming increasingly important for homeowners. Both acrylic and solid surface are manufactured products, meaning their production has an environmental impact. However, many manufacturers are making strides in sustainability. Some offer products with recycled content or are working towards more eco-friendly production processes. Both materials are also generally considered low in VOCs (Volatile Organic Compounds), contributing to better indoor air quality. When making a choice, it’s worth inquiring about the specific environmental certifications and manufacturing practices of the brands you are considering.

Cost, as always, plays a significant role. Generally speaking, 100% acrylic solid surfaces can sometimes be at the higher end of the solid surface price spectrum, particularly for those with very complex patterns or unique colors. Composite solid surfaces can offer a broader range of price points, with some more budget-friendly options available, especially for simpler designs and colors. However, it’s crucial to get detailed quotes from fabricators, as the cost of fabrication, installation, and complexity of the design can significantly influence the final price, often more so than the material cost alone.

When comparing to other popular materials, let’s briefly touch upon quartz and granite. Quartz is an engineered stone, typically composed of about 90% ground quartz and 10% polymer resins and pigments. It is extremely hard, highly resistant to scratches and heat, and non-porous. Its primary downside is its inability to be thermoformed into seamless shapes, and repairs to chips or cracks can be more complex than with solid surfaces. Granite, a natural stone, offers unique beauty and durability but is porous and requires regular sealing to prevent staining. It’s also susceptible to etching from acidic substances. Compared to these, solid surface materials offer a more forgiving combination of workability, seamlessness, and repairability, albeit with slightly less scratch and heat resistance.

In conclusion, the distinction between acrylic and solid surface, while sometimes subtle, is important for discerning consumers. Acrylic solid surfaces often offer superior translucency for backlighting and may provide greater flexibility in thermoforming intricate shapes. They can also have a distinct tactile feel. Composite solid surfaces, on the other hand, might offer a wider range of price points and a feel that some find more akin to natural stone. Both are excellent choices for seamless, hygienic, and repairable surfaces. The “better” material ultimately depends on your specific design aspirations, budget, and how you intend to use the surface in your daily life. By understanding these pros and cons, you are well-equipped to select a material that will not only enhance the beauty of your space but also serve you reliably for years to come.