In the ever-evolving landscape of interior design and home renovation, the choice of materials plays a pivotal role in shaping both the aesthetics and functionality of our living spaces. Among the most popular contenders for surfaces like countertops, vanities, and even wall cladding, you’ll often find acrylic solid surface and its close cousin, engineered stone (often mistakenly referred to as just “solid surface” in a broader sense). While they share a superficially similar appearance, these two materials are distinct in their composition, properties, and suitability for various applications. This article, presented as a comprehensive visual and auditory guide, aims to demystify the differences between acrylic solid surface and engineered stone, empowering you to make the most informed decision for your next design endeavor.

Imagine, if you will, the tactile sensation of running your hand over a perfectly smooth, cool surface. Both acrylic solid surface and engineered stone can offer this satisfying experience. However, the journey to achieving that finish, and the inherent qualities of the material itself, diverge significantly.

Let’s begin with acrylic solid surface. Think of it as a meticulously crafted composite. Its primary ingredient is a type of acrylic polymer, the same family of plastics found in everything from durable eyewear lenses to vibrant signage. This polymer is then combined with natural minerals, primarily aluminum trihydrate (ATH), a white powder derived from bauxite ore. Pigments are added to achieve an astonishing spectrum of colors and patterns, from pristine whites and deep blacks to intricate veining that mimics natural stone. This mixture is then cast into sheets or molded into specific shapes. The result is a non-porous, homogeneous material that is uniform throughout its thickness.

To truly grasp the essence of acrylic solid surface, let’s engage our senses. Visually, it often presents a more uniformly colored or subtly patterned appearance. Picture a perfectly blended smoothie, where the colors are evenly distributed, creating a smooth, consistent hue. When light hits it, it tends to have a softer, more diffused glow, rather than the sharp, crystalline reflections you might see in some natural stones. If you were to tap on an acrylic solid surface countertop, the sound would likely be a duller, more muted thud, akin to tapping on a dense, high-quality plastic. There’s a certain warmth to its touch, a subtle yielding that speaks to its polymeric nature.

The fabrication process for acrylic solid surface is where its unique advantages truly shine. Because it’s a thermosetting polymer, it can be heated and thermoformed. This means it can be bent, curved, and molded into virtually any shape imaginable. This ability to be sculpted is akin to working with clay; designers can bring flowing, organic forms to life without the limitations of cutting and seaming. Furthermore, acrylic solid surface can be seamlessly joined. When two pieces are glued together with a specialized adhesive that chemically bonds with the material, the seam becomes virtually invisible. Imagine a perfectly orchestrated symphony where no individual instrument’s note stands out jarringly; the entire piece flows as one cohesive entity. This seamlessness is a hallmark of high-end design, eliminating unsightly grout lines or visible joints that can trap dirt and bacteria.

The non-porous nature of acrylic solid surface is another critical advantage. Unlike natural stone or even some other composite materials, it does not absorb liquids. Think of it as a perfectly sealed shield. Spills of wine, coffee, or oil will bead up on the surface, ready to be wiped away without leaving a stain. This inherent resistance to staining makes it incredibly hygienic and low-maintenance. Cleaning is usually as simple as a damp cloth and mild soap. Even if a scratch or minor damage occurs, it can often be repaired. Because the color and pattern run through the entire thickness of the material, a skilled fabricator can sand down the affected area, essentially restoring it to its original pristine condition. This reparability is like having a magic eraser for your surfaces, allowing them to maintain their beauty for years to come.

In terms of durability, acrylic solid surface is quite robust. While it can be scratched if subjected to sharp objects or abrasive cleaners, it’s generally resistant to chipping and cracking, especially compared to brittle materials like certain types of tile. Its flexibility, a result of its polymeric base, absorbs some impact, preventing fractures.

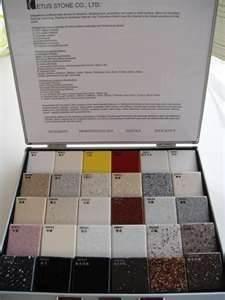

Now, let’s pivot our attention to its counterpart, engineered stone, often referred to as quartz or quartz composite. While the term “solid surface” can broadly encompass acrylics, in the context of differentiating materials, “engineered stone” is the more precise term for what’s commonly found alongside acrylic solid surface in showrooms. Engineered stone is a triumph of material science, created by combining crushed natural quartz crystals (about 90-95%) with a polymer resin binder and pigments. The quartz provides the material’s inherent strength and durability, while the resin acts as a binder and provides flexibility.

To visualize engineered stone, think of a precisely engineered mosaic. Instead of individual tiles, you have finely crushed fragments of quartz suspended in a binder. The visual appearance is often characterized by a more granular or crystalline look, even in patterns designed to mimic natural stone. When light hits engineered stone, it can reflect and refract off the quartz crystals, creating a more sparkling or shimmering effect, much like sunlight glinting off a field of tiny diamonds. If you were to tap on an engineered stone countertop, the sound would likely be a sharper, more resonant ‘clack’ or ‘ping,’ indicative of its harder, mineral-based composition. It feels inherently harder and colder to the touch, reflecting its mineral content.

The fabrication of engineered stone is more akin to working with stone or dense tile. It is typically cut and shaped using specialized saws and routers. While advanced techniques allow for some shaping, it doesn’t possess the same thermoforming capabilities as acrylic solid surface. Seams are a necessary part of engineered stone installations. While fabricators strive to make these seams as inconspicuous as possible, they will generally be visible, especially in intricate patterns or on longer runs. Imagine carefully placed grout lines in a tiled floor; they serve a functional purpose but are an observable part of the overall design.

However, engineered stone’s primary strength lies in its exceptional hardness and durability, largely due to the high concentration of quartz. It is incredibly resistant to scratches, heat, and staining. The resin binder, while providing some flexibility, also makes the material non-porous, meaning it won’t absorb liquids or harbor bacteria. This makes it incredibly hygienic and easy to maintain. Cleaning is typically done with mild soap and water, though it’s advisable to avoid harsh chemicals or abrasive pads that could dull the resin’s finish.

The density and hardness of engineered stone mean it’s highly resistant to etching from acidic substances like lemon juice or vinegar. It can also generally withstand hot pots and pans placed directly on its surface, though using trivets is always recommended to preserve the resin’s integrity. Unlike natural stone, engineered stone’s color and pattern are consistent throughout the slab, ensuring uniformity in appearance.

So, as we’ve journeyed through the sensory landscape of these two remarkable materials, the distinctions begin to crystallize. Acrylic solid surface offers unparalleled design flexibility, seamless integration, and a warmer, more homogeneous aesthetic. Engineered stone, on the other hand, champions extreme hardness, heat resistance, and a more crystalline, reflective appearance. The choice between them hinges on the priorities of your project: whether you value the boundless creative potential of acrylic or the formidable resilience of engineered stone.

Continuing our deep dive into the world of acrylic solid surface and engineered stone, we move from understanding their fundamental compositions and sensory characteristics to exploring their practical implications in real-world applications. The differences we’ve touched upon – flexibility, seam visibility, heat resistance, and repairability – translate into distinct advantages and considerations when selecting the right material for your kitchen countertops, bathroom vanities, or even more avant-garde design projects.

Let’s revisit the visual and auditory cues, this time focusing on how they manifest in finished installations. Imagine walking into a kitchen. If you see countertops with sweeping curves that seamlessly blend into a backsplash, or a sink that appears to be sculpted directly from the countertop material itself, you are likely looking at acrylic solid surface. The seamless nature, as we discussed, means there are no visible grout lines or abrupt transitions. This creates an unbroken expanse of color and texture, contributing to a minimalist, clean, and modern aesthetic. If you were to place your ear close to the edge of an acrylic countertop and tap it lightly, you’d again hear that softer, more subdued sound, a testament to its composite nature. It’s a material that whispers elegance rather than shouts for attention, blending harmoniously into the overall design.

In contrast, a kitchen featuring engineered stone countertops might showcase a more structured and perhaps more traditional look, even with contemporary designs. The visible seams, though minimized by skilled fabrication, will be present, especially at corners or where multiple slabs meet. This isn’t necessarily a drawback; for many, it’s an accepted characteristic of a durable, stone-like material. The visual texture of engineered stone, with its flecks and crystals, can add a dynamic sparkle to the space. When light catches these quartz particles, it creates a lively, shimmering effect, akin to a starry night sky. Tapping on an engineered stone surface would produce that sharper, more resonant sound, hinting at its inherent hardness and mineral composition. It’s a material that asserts its presence with a confident, solid feel.

When it comes to the practicalities of daily life, the differences become even more pronounced. Consider a busy family kitchen. If spills are a frequent occurrence – and let’s be honest, in most kitchens, they are – the non-porous nature of both materials is a significant boon. However, the way they handle those spills and potential damage differs. Acrylic solid surface’s inherent flexibility means it’s less prone to chipping or cracking under impact. If a heavy pot accidentally slips from your grasp and lands on the edge of an acrylic countertop, there’s a greater chance it will absorb some of the shock without resulting in a visible chip. More importantly, should a scratch or a minor burn mark occur on an acrylic surface, it can often be buffed out and repaired on-site by a qualified professional. This is a major advantage for longevity and maintaining that pristine appearance. Think of it as a high-quality leather jacket that, with a bit of conditioning and polishing, can look new again after years of wear.

Engineered stone, while incredibly hard and scratch-resistant, can be more brittle. A significant impact, especially on an edge or corner, could lead to a chip or even a crack. While resistant to heat, placing extremely hot items directly on the surface for extended periods can, in some cases, cause discoloration or damage to the resin binder. Repairing chips or cracks in engineered stone is often more complex and may require professional intervention, potentially involving color-matching epoxy or even slab replacement depending on the severity. It’s more akin to repairing a ceramic tile; while possible, it’s often more challenging to achieve a completely invisible fix.

Let’s delve into specific applications. In a bathroom, the seamless and non-porous nature of acrylic solid surface makes it an ideal choice for integrated sinks and vanities. You can have a countertop that flows directly into a basin, eliminating seams where water and soap can collect. This creates a hygienic and easy-to-clean environment, perfect for a space where cleanliness is paramount. The ability to thermoform acrylic also allows for unique curved vanity designs that might be impossible or prohibitively expensive with other materials.

Engineered stone also excels in bathrooms, offering a luxurious and durable surface. Its resistance to moisture and staining makes it suitable for vanities, and its wide range of colors and patterns can complement various design styles. However, the potential for visible seams in larger vanity tops or around integrated sinks is a factor to consider.

Beyond the kitchen and bathroom, both materials find their way into commercial spaces and architectural features. Acrylic solid surface is favored for reception desks, healthcare surfaces (due to its hygiene and seamlessness), and intricate architectural elements where complex curves and shapes are desired. Its ability to be backlit also opens up unique design possibilities, creating a soft, ethereal glow.

Engineered stone is a staple in high-traffic commercial areas, hotels, and restaurants, valued for its extreme durability and resistance to wear and tear. Its consistent appearance makes it ideal for large-scale installations where uniformity is key.

When it comes to maintenance, both materials are relatively low-maintenance compared to natural stone. Acrylic solid surface typically requires mild soap and water for cleaning. For tougher stains, a non-abrasive cleaner can be used, and deep scratches can be professionally repaired. The key is to avoid harsh solvents and abrasive pads.

Engineered stone also benefits from simple cleaning with mild soap and water. It’s important to wipe up spills promptly, especially acidic ones, to prevent any potential dulling of the resin. While it’s heat-resistant, using trivets is always a wise precaution to ensure the longevity of the resin binder.

Ultimately, the decision between acrylic solid surface and engineered stone comes down to prioritizing your design goals and practical needs. If your vision includes seamless integration, organic shapes, unparalleled design flexibility, and the ability to repair minor damage with ease, acrylic solid surface is likely your ideal material. It offers a sophisticated, understated elegance and a hygienic, low-maintenance surface.

If, however, your priorities lie in exceptional hardness, superior resistance to heat and scratches, and a visually dynamic, crystalline appearance, then engineered stone is the superior choice. It provides a robust, long-lasting surface that can withstand the rigors of daily use with minimal fuss.

By engaging your sense of sight and sound, and considering the practicalities of fabrication, durability, and maintenance, you can confidently navigate the choices available. Both acrylic solid surface and engineered stone are modern marvels, offering beautiful and functional solutions. Understanding their core differences allows you to select the material that will not only meet your aesthetic desires but also serve you reliably for years to come, transforming your spaces into functional works of art.