Acrylic vs. Solid Surface: Decoding the Differences for Your Dream Surfaces

The quest for the perfect surface in home design often leads us down a fascinating path of material exploration. Two frontrunners that frequently capture attention for their versatility and modern appeal are acrylic and solid surface. While often grouped together due to their similar visual fluidity and seamless integration possibilities, these materials are distinct entities with unique properties that cater to different needs and aesthetic desires. Understanding these differences is key to unlocking the full potential of your design vision, whether it’s for a sleek, minimalist kitchen island, a durable and hygienic bathroom vanity, or a custom-designed commercial space.

Let’s begin by demystifying acrylic, often referred to as acrylic solid surface or simply “acrylic” in the context of countertops and surfacing. At its core, acrylic is a thermoplastic polymer, a type of plastic known for its clarity, strength, and moldability. When manufactured for surfacing applications, it’s combined with mineral fillers and pigments to create a solid, non-porous material. The magic of acrylic lies in its remarkable thermoformability. This means it can be heated and molded into virtually any shape imaginable – gentle curves, intricate edges, and even complex three-dimensional forms. This inherent plasticity grants designers an extraordinary degree of freedom, allowing for truly bespoke creations that transcend the limitations of traditional materials like stone or wood. Think of dramatic waterfall edges that flow uninterrupted, integrated sinks that blend seamlessly into the countertop, or even curved reception desks that command attention.

One of the most celebrated attributes of acrylic solid surface is its non-porous nature. This is a significant advantage, particularly in high-moisture or high-traffic areas. Unlike natural stone, which can absorb liquids and harbor bacteria, acrylic’s dense, impervious surface repels stains and is exceptionally hygienic. Spills from wine, coffee, or juice are no match for its resilient composition, making cleanup a breeze. This inherent resistance to staining and bacterial growth makes it an ideal choice for kitchens where food preparation is frequent, and for bathrooms where sanitation is paramount. Furthermore, its non-porous quality means it doesn’t require sealing, a common maintenance task associated with granite and marble.

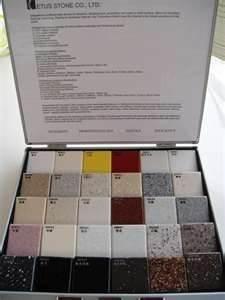

The aesthetic possibilities with acrylic are vast. Available in an extensive palette of colors, from crisp whites and deep blacks to vibrant hues and subtle earth tones, acrylic can adapt to any design scheme. Many acrylic products also feature integrated patterns and flecks, mimicking the look of natural stone or offering unique, abstract designs. The true beauty of acrylic, however, often lies in its ability to achieve seamless fabrication. When pieces of acrylic solid surface are joined, the seams can be glued with a specialized adhesive that melts the material together, creating a bond that is virtually invisible. This allows for expansive, uninterrupted surfaces that enhance the feeling of spaciousness and sophistication in a room. No more unsightly grout lines or obvious joins – just pure, flowing form.

However, it’s important to acknowledge that acrylic, being a type of plastic, does have certain limitations. While durable, it is more susceptible to scratching and heat damage than some other materials. Deep scratches can often be repaired through sanding and polishing, a testament to its solid composition throughout, but significant heat exposure, such as placing a hot pot directly on the surface, can cause discoloration or warping. This necessitates the use of trivets and cutting boards, a practice that is generally recommended for most countertop materials anyway. Despite these considerations, the unparalleled design flexibility, hygienic properties, and seamless aesthetic of acrylic make it a compelling choice for those seeking a modern, adaptable, and visually striking surface solution. It’s a material that invites creativity and pushes the boundaries of what we expect from our built environments.

Now, let’s pivot to its close cousin, often found in the same design conversations: solid surface. It’s easy to see why these two get conflated. Solid surface is, in essence, a composite material typically made from acrylic or polyester resins, mixed with mineral fillers (often bauxite-derived alumina trihydrate – ATH), pigments, and other additives. While acrylic solid surface is a specific type of solid surface where acrylic resin is the primary binder, the term “solid surface” can encompass a broader range of formulations, including those predominantly using polyester resins. For the purpose of this comparison, when we refer to “solid surface,” we are generally speaking of the broader category, acknowledging that many high-quality solid surfaces also utilize acrylic as a key component, and thus share many of its benefits, including the non-porous nature and seamless integration.

The distinction, however, becomes more nuanced when considering the manufacturing and performance characteristics. Solid surface materials, like acrylic, are manufactured in sheets or shapes, offering a consistent quality and appearance. They are also inherently non-porous, meaning they resist staining and bacteria, making them a hygienic choice for kitchens, bathrooms, and healthcare settings. The seamless joining capability is also a hallmark of solid surface, allowing for visually uninterrupted installations and integrated sinks, just as with acrylic. This shared characteristic is a major draw for designers and homeowners alike, providing a clean, modern aesthetic.

The range of colors and patterns available in solid surface is also extensive, offering a diverse palette to complement any interior design. From subtle marbling and granite-like speckles to bold, contemporary colors, solid surface can be tailored to fit various styles. Its ability to be thermoformed also allows for curves and custom shapes, though the degree of flexibility and the complexity of shapes achievable might vary slightly depending on the specific resin composition. Generally, materials with a higher acrylic content tend to offer greater thermoforming capabilities and a more “plastic-like” feel, while polyester-based solid surfaces might be slightly more rigid.

Durability is another key shared trait. Solid surfaces are engineered for resilience, resisting impact and wear. Like acrylic, they are generally repairable. Minor scratches or chips can often be sanded out, restoring the surface to its original condition. This reparability is a significant advantage over materials like laminate or even some natural stones that can be permanently damaged by a single unfortunate incident. The ability to refresh and revive a solid surface over time contributes to its longevity and value.

The subtle differences often come down to the specific resin systems and manufacturing processes. While both are non-porous and seamless, acrylic-rich formulations might offer slightly superior resistance to chemicals and UV degradation. Polyester-based solid surfaces, on the other hand, might exhibit greater hardness and thus a slightly better resistance to scratching in some formulations. However, for most residential applications, the performance differences between high-quality acrylic solid surface and other types of solid surface are often negligible to the end-user, especially when considering the overall benefits they both provide. The decision often boils down to specific product lines, manufacturer warranties, and the precise aesthetic nuances that appeal most to the individual.

In essence, both acrylic and solid surface materials stand out as excellent choices for modern surfacing needs. They offer a compelling combination of aesthetics, hygiene, and adaptability. The overlap in their properties, particularly the non-porous nature and seamless fabrication, makes them strong contenders for anyone looking to upgrade their kitchen countertops, bathroom vanities, or other surfaces. As we move into the second part of our exploration, we will delve deeper into the practical considerations, installation nuances, and aesthetic comparisons that will help you make the definitive choice between these two exceptional materials.

Continuing our journey into the world of acrylic and solid surface, we’ve established their shared strengths: non-porosity, seamless integration, and a vast array of design possibilities. Now, let’s refine our understanding by exploring the finer points of performance, cost, installation, and maintenance, which will truly help distinguish them for your specific project needs.

When it comes to heat resistance, both acrylic and solid surface materials generally perform well under normal kitchen use, but direct, prolonged exposure to high heat can be an issue for both. Neither material is as heat-resistant as natural stone like granite or quartz. Placing hot pots, pans, or baking sheets directly onto the surface is ill-advised and can lead to discoloration, scorching, or even warping. The use of trivets and hot pads is an essential practice for maintaining the pristine condition of both acrylic and solid surface countertops. Some manufacturers may offer specific formulations with enhanced heat resistance, so it’s always worth checking product specifications. However, as a general rule, treat them with respect when it comes to extreme heat.

Scratch resistance is another area where subtle differences can emerge, though again, the variability between specific product lines is significant. Acrylic, being a polymer, can be more prone to superficial scratches than some of the harder mineral-filled formulations found in certain solid surfaces. However, the advantage of acrylic, and indeed all solid surfaces, is their “solid” nature. Unlike laminate, where the decorative layer is merely a thin print, the color and pattern in acrylic and solid surface extend all the way through the material. This means that minor scratches and scuffs can often be buffed out or sanded away by a professional, restoring the surface to its original glory. This reparability is a key selling point and a significant advantage in terms of long-term value and appearance. A well-maintained solid surface or acrylic countertop can look new for years, even after encountering everyday wear and tear.

Cost is an undeniable factor in any renovation project, and here, both materials typically sit in a mid-to-high price range, often comparable to mid-grade natural stone or quartz. The exact cost will vary significantly based on the brand, the complexity of the design, the chosen color and pattern (more complex or exotic looks often cost more), and the fabrication and installation required. Seamless integration and complex shapes, which are hallmarks of both acrylic and solid surface, can increase labor costs. However, when you factor in the seamless sinks and the elimination of backsplash seams, the overall cost can sometimes be more competitive than traditional materials where separate sink installations and potentially separate backsplash materials are needed. It’s a good idea to get detailed quotes from fabricators for specific designs to accurately compare costs.

Installation of both acrylic and solid surface is typically carried out by trained professionals. The material is cut to size in a workshop, and then brought to the site for final fitting and seaming. The ability to achieve invisible seams is a key part of the installation process, requiring specialized adhesives and techniques. This is where the expertise of the fabricator becomes crucial. For integrated sinks, the sink bowl is often fabricated from the same solid surface material and then bonded seamlessly to the countertop. This creates a sleek, hygienic, and visually unified look that is difficult to achieve with other materials. The installation process for complex curved or custom shapes will naturally require more time and skill, impacting the overall project timeline and budget.

Maintenance for both materials is refreshingly straightforward, a major reason for their popularity. Due to their non-porous nature, they resist staining from common household liquids like coffee, wine, and juice. A simple wipe-down with a damp cloth and mild soap is usually sufficient for daily cleaning. For tougher stains, a non-abrasive household cleaner can be used. It’s advisable to avoid abrasive cleaners or scouring pads, as these can dull the finish over time. As mentioned, the key maintenance practice for both is the consistent use of trivets and cutting boards to protect against heat and deep scratches. Regular cleaning and occasional buffing (for minor dulling) will keep both acrylic and solid surface looking their best for years to come.

When it comes to aesthetic nuances, this is where personal preference truly comes into play. Acrylics, especially those with a higher acrylic resin content, can sometimes have a slightly warmer, more “plastic-like” feel to the touch, and may offer a more luminous quality in certain colors. They can also be clearer or more translucent in some formulations, allowing for backlighting effects that are truly stunning. Solid surfaces, with their broader range of resin types and fillers, can sometimes offer a wider spectrum of textures and finishes, from matte to high-gloss, and a greater variety of stone-like appearances. However, the lines are increasingly blurred as manufacturers innovate. Many high-end solid surfaces are virtually indistinguishable from premium acrylics in terms of feel and appearance.

Ultimately, the choice between acrylic and solid surface often comes down to the specific product line, the manufacturer’s reputation, and the precise aesthetic and performance characteristics that align with your vision. While the term “solid surface” is broader, and “acrylic solid surface” is a specific type within that category, both offer a compelling combination of durability, hygiene, design flexibility, and seamless beauty.

If your priority is the absolute maximum in thermoforming capability for highly complex, sculptural shapes, or if you’re drawn to a material that feels inherently luminous and smooth, a high-quality acrylic solid surface might have a slight edge. If you are looking for a vast range of stone-like patterns, a slightly more varied texture selection, or perhaps a slightly more cost-effective option within the premium surfacing category (depending on the specific product), then exploring the wider world of solid surfaces, which may include acrylic-based formulations, is a great path to take.

Both materials represent a significant step up from older surfacing technologies, offering a blend of form and function that is hard to beat. By understanding their shared strengths and subtle differences, you are well-equipped to select the material that will not only meet your practical needs but also elevate the aesthetic of your home for years to come. The world of surfaces is rich with possibilities, and acrylic and solid surface are shining examples of modern material innovation.