The world of interior design and renovation is a fascinating landscape, filled with materials that promise both aesthetic appeal and practical functionality. When it comes to surfaces, particularly for kitchens, bathrooms, and commercial applications, two popular contenders often emerge: acrylic and solid surface. While they might appear similar at first glance, boasting seamless joints and a wide array of colors, these materials possess distinct characteristics that can significantly impact their suitability for your specific project. Understanding these nuances is key to unlocking the full potential of your design and ensuring a lasting, beautiful result.

Acrylic, often referred to by brand names like Corian (though Corian is a specific type of solid surface, the general understanding often conflates the two), is a type of polymer composite. It’s known for its non-porous nature, which translates to excellent resistance against stains and bacteria. This makes it a hygienic choice, particularly appealing for healthcare settings and busy family kitchens. One of acrylic’s most lauded advantages is its thermoformability. This means it can be heated and molded into virtually any shape, allowing for incredible design flexibility. Imagine a waterfall countertop that flows seamlessly down the side of a cabinet, or a custom-shaped sink integrated directly into the countertop without any visible seams. This ability to create intricate curves and organic forms opens up a world of design possibilities that are often unattainable with more rigid materials.

Beyond its shape-shifting capabilities, acrylic offers a remarkably smooth and warm-to-the-touch feel. This tactile quality adds a layer of luxury and comfort to any space. Its non-porous surface also means that spills, whether it’s red wine, coffee, or cooking oil, tend to stay on the surface, making them easy to wipe away without fear of permanent staining or absorption into the material. This ease of maintenance is a huge selling point for homeowners and facility managers alike. Furthermore, acrylic is repairable. Minor scratches or chips can often be buffed out or repaired by a professional, restoring the surface to its original glory. This repairability contributes to its long-term value and sustainability, as it extends the lifespan of the material.

However, like any material, acrylic isn’t without its drawbacks. While it’s durable, it’s not as hard as natural stone or some other composite materials. This means it can be more susceptible to scratching from sharp objects or abrasive cleaning tools. While scratches can be repaired, the need for this maintenance is something to consider. Additionally, prolonged exposure to extreme heat can cause damage. While it can withstand a hot pan placed on it for a brief period (especially if a trivet is used), leaving a very hot pot directly on the surface for an extended time could lead to discoloration or even warping. This requires a bit more mindfulness in the kitchen, ensuring that hot items are always placed on protective surfaces.

Color consistency is another aspect to ponder. While acrylic is available in a vast spectrum of colors and patterns, it’s important to note that color matching can sometimes be a challenge, especially if you need to replace a section of an existing installation. While manufacturers strive for consistency, subtle variations can occur between batches. Therefore, keeping any leftover material or detailed records of the original purchase is advisable. When it comes to cost, acrylic generally falls in a mid-to-high price range, depending on the complexity of the design and the specific brand chosen. While it might not be the most budget-friendly option upfront, its longevity, repairability, and aesthetic versatility can offer a strong return on investment over time.

In the realm of solid surface materials, acrylic represents a significant portion, but the term “solid surface” itself is broader. It encompasses a range of composite materials, often made from a blend of acrylic polymers and mineral fillers, such as bauxite. This composition contributes to its strength and durability. The defining characteristic of all solid surfaces, including acrylic-based ones, is their homogenous nature. This means the color and pattern run through the entire thickness of the material, which is crucial for both aesthetics and repair. Unlike materials with a veneer or a laminated top layer, if solid surface gets scratched or damaged, the underlying material is the same, allowing for seamless repairs.

The non-porous nature of solid surface is a significant advantage, offering excellent resistance to moisture, stains, and bacteria. This makes it an ideal choice for kitchens, bathrooms, and any environment where hygiene is paramount. The seamless installation capability is another major draw. Because solid surface can be cut, shaped, and joined with specialized adhesives that match the material’s color, seams are virtually invisible. This creates a sleek, modern look and eliminates the crevices where dirt and bacteria can accumulate. This is particularly beneficial for integrated sinks and backsplashes, which contribute to a unified and easy-to-clean design.

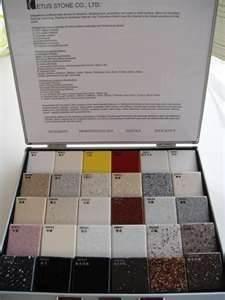

The variety of colors, patterns, and textures available in solid surface materials is astounding. From mimicking the look of natural stone like granite or marble to offering bold, contemporary hues and unique veining, there’s a solid surface option to complement almost any design aesthetic. The ability to thermoform solid surface, similar to acrylic, allows for curved countertops, custom-designed sinks, and other complex shapes, offering a high degree of design freedom. This adaptability makes it a favorite among designers and architects looking to create unique and personalized spaces.

However, the perceived hardness of solid surface can sometimes be misleading. While it is more resistant to scratching than some softer materials, it is not impervious to damage. Sharp objects or abrasive cleaners can still leave their mark. The repair process for solid surface is generally effective, involving sanding and buffing to remove scratches. Deeper gouges or chips may require professional attention, but the fact that the material is homogenous means repairs are often undetectable.

Heat resistance is another area where caution is advised. While solid surface can handle moderate heat, placing extremely hot items directly onto the surface for extended periods can cause thermal shock, leading to discoloration or cracking. Using trivets and heat pads is always recommended. When considering cost, solid surface materials generally sit in the mid-to-high price bracket, with variations depending on the brand, complexity of the design, and installation requirements. While the initial investment might be higher than some laminate or tile options, the benefits of durability, hygiene, seamless design, and repairability often make it a worthwhile long-term investment. The maintenance is relatively low, but understanding the material’s limitations regarding heat and sharp objects is key to preserving its pristine appearance.

Delving deeper into the practicalities of acrylic and solid surface materials reveals a spectrum of considerations that are crucial for any discerning homeowner or designer. While both share the common ground of being engineered composites designed for durability and aesthetic appeal, their distinct compositions lead to subtly different performance characteristics and maintenance requirements. The choice between them often hinges on the specific demands of the application, the desired visual outcome, and the willingness to engage in particular care routines.

Acrylic, in its purest form as a standalone polymer, often possesses a slightly softer quality compared to some solid surface blends that incorporate denser mineral fillers. This inherent characteristic means that while acrylic is remarkably resistant to stains and chemicals due to its non-porous structure, it can be more prone to developing superficial scratches. Think of it like a high-gloss car finish – it looks stunning, but it can show swirl marks if not treated with care. For kitchens, this translates to a need for a little more vigilance when chopping or preparing food directly on the surface. While a cutting board is always recommended for any countertop material, with acrylic, it becomes more of a necessity to maintain its pristine look. However, the beauty of acrylic lies in its repairability. A skilled fabricator can often buff out minor scratches, making them virtually disappear. For more significant damage, techniques like sanding and refinishing can restore the surface to its original sheen. This ability to be rejuvenated is a significant advantage, allowing the material to maintain its appeal for years, even with regular use.

The thermoforming capability of acrylic is a truly remarkable aspect that sets it apart in design possibilities. This property allows the material to be heated and molded into virtually any three-dimensional shape. This opens the door for truly bespoke designs, such as intricate curved countertops, integrated sinks that flow seamlessly from the countertop, and unique architectural elements. For a designer seeking to push creative boundaries or a homeowner wanting a truly one-of-a-kind space, acrylic offers an unparalleled level of design freedom. The seamless integration of sinks, for example, eliminates the traditional caulked or metal-rimmed joints that can harbor bacteria and detract from a clean aesthetic. This creates a monolithic and hygienic surface that is both beautiful and highly functional.

However, this flexibility comes with a caveat: heat resistance. While acrylic can withstand moderate temperatures, direct contact with very hot objects, such as a skillet taken directly off the stove, can cause permanent damage. This can manifest as discoloration, a dulling of the surface, or even slight warping. Therefore, the consistent use of trivets and hot pads is non-negotiable when working with acrylic in a kitchen environment. This is a maintenance consideration that, while manageable, requires a conscious effort and a shift in habits for those accustomed to placing hot items directly on their countertops. The cost of acrylic can also be a factor. While it offers excellent value for its durability, repairability, and design versatility, it generally sits in the mid-to-high price range, with prices varying based on the complexity of the fabrication and the specific manufacturer.

Shifting our focus to solid surface materials, which often include acrylic polymers blended with mineral fillers like alumina trihydrate (ATH), we find a material that aims to strike a balance between form and function. The addition of mineral fillers generally imparts a greater degree of hardness and density to the material compared to pure acrylic. This can translate to a slightly improved resistance to scratching and impact. While still not as hard as granite or quartz, a solid surface countertop might offer a touch more resilience in a busy kitchen environment. The homogenous nature of all solid surface materials is a key differentiator. This means that the color and pattern extend through the entire thickness of the slab. This is critically important for repairs. A scratch or chip on a solid surface material can be sanded down and buffed out, and because the material beneath is the same color and pattern, the repair is often virtually undetectable. This inherent repairability contributes significantly to the longevity and aesthetic integrity of the surface.

The non-porous quality of solid surface is a significant advantage, contributing to its hygienic properties and stain resistance. Spills are easily wiped away, and the material is resistant to the growth of mold and mildew, making it an excellent choice for bathrooms and kitchens. Similar to acrylic, solid surface materials can be thermoformed, allowing for a good degree of design flexibility. While perhaps not as infinitely moldable as pure acrylic in some instances, it still enables the creation of seamless integrated sinks, curved edges, and other custom features. This ability to create a cohesive, flowing design eliminates unsightly seams and provides a smooth, easy-to-clean surface.

The range of aesthetic options available in solid surface materials is vast. From realistic imitations of natural stone to contemporary solid colors and unique veining patterns, designers have a wide palette to choose from. This versatility allows solid surface to adapt to a multitude of interior design styles. However, like acrylic, solid surface materials are not immune to heat damage. Extreme temperatures can cause discoloration or thermal shock. Therefore, the consistent use of protective pads for hot cookware remains essential. The cost of solid surface materials typically places them in a similar mid-to-high price bracket as acrylic, with variations influenced by brand, color, pattern complexity, and fabrication techniques. The initial investment reflects the material’s durability, seamless aesthetic, hygienic properties, and repairability.

When comparing the two head-to-head, the decision often boils down to a nuanced assessment of priorities. If the absolute zenith of design flexibility, including intricate curves and truly unique sculpted forms, is paramount, and you are meticulous about using trivets, pure acrylic might edge out. Its ability to be manipulated into almost any shape is its superpower. On the other hand, if a slightly greater degree of scratch resistance in a busy household, coupled with the inherent benefits of a homogenous, repairable, and hygienic surface, is the focus, solid surface (which often includes acrylic as a component) presents a compelling case.

The term “solid surface” is a broader category, and many high-quality solid surface materials are indeed acrylic-based, incorporating mineral fillers for enhanced properties. So, in essence, you are often choosing between different formulations and compositions within the broader solid surface family. The key takeaway is that both acrylic and solid surface materials offer excellent performance characteristics, providing a seamless, non-porous, and aesthetically pleasing surface. Their differences lie in the subtle variations in their composition, leading to slightly different levels of scratch resistance, thermoforming capabilities, and cost implications. Ultimately, a thorough understanding of these distinctions, coupled with a clear vision for your project, will guide you toward the material that best meets your needs and aspirations, ensuring a beautiful, functional, and enduring addition to your home or establishment.