Sure, I can help you with that! Here is a soft article comparing artificial acrylic stone and artificial quartz stone, presented in two parts as requested.

Unveiling the Allure of Surfaces – Acrylic vs. Quartz

The Genesis of Beauty – Understanding Acrylic and Quartz

In the ever-evolving landscape of interior design and architecture, the choice of surface material plays a pivotal role in defining a space’s character, functionality, and lasting appeal. Among the most celebrated and versatile options are artificial stones, a category that has revolutionized how we envision countertops, backsplashes, wall cladding, and even furniture. Within this domain, two prominent contenders often emerge: artificial acrylic stone and artificial quartz stone. While both offer a wealth of design possibilities and a departure from the limitations of natural materials, they possess distinct origins, properties, and performance characteristics that cater to different needs and aspirations. Understanding these nuances is the first step in unlocking their full potential and making an informed decision that will resonate with your aesthetic vision and practical requirements.

Artificial acrylic stone, often referred to by brand names like Corian, is a composite material that ingeniously blends acrylic polymer resin with a high concentration of natural minerals, primarily alumina trihydrate (ATH). This union results in a non-porous, homogeneous material that can be thermoformed, meaning it can be heated and shaped into seamless curves and intricate designs. Imagine a countertop that flows effortlessly into a sink, or a reception desk with elegantly sculpted contours – this is the magic that acrylic solid surfaces can conjure. The acrylic resin acts as a binder, imbuing the material with its characteristic workability and a certain degree of flexibility. The ATH, derived from bauxite ore, contributes to its fire retardant properties and provides a matte or semi-gloss finish that feels warm and inviting to the touch, unlike the often cooler feel of stone.

The manufacturing process for acrylic solid surfaces involves mixing the acrylic polymer, ATH, and pigments to achieve a desired color and pattern. This mixture is then cast into large sheets, which are subsequently cut to size and finished. The beauty of acrylic lies in its inherent translucency, allowing for a captivating play of light and depth within its colors and patterns. It can mimic the appearance of natural stone, wood, or even introduce entirely new, vibrant hues and intricate veining that are not found in nature. One of its most compelling advantages is its repairability. Minor scratches, chips, or even deeper gouges can often be buffed out or repaired by trained professionals, effectively restoring the surface to its original pristine condition. This makes it a remarkably resilient choice for high-traffic areas where wear and tear are a consideration.

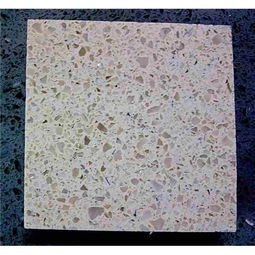

On the other hand, artificial quartz stone, also known as engineered quartz, is a testament to the power of engineering and innovation. It is a composite material predominantly composed of ground natural quartz crystals, bound together by a polymer resin, typically polyester or acrylic. This composition usually consists of an overwhelming majority of quartz – often around 90-93% – with the remainder being resins and pigments. The sheer abundance of natural quartz crystals is what gives engineered quartz its remarkable hardness, durability, and resistance to stains and scratches. Unlike acrylic, which is cast, quartz slabs are typically manufactured using a process called the Bretonstone process, which involves vibrating and compressing the mixture under vacuum. This process eliminates air voids and creates an incredibly dense and robust material.

The aesthetic versatility of artificial quartz is equally impressive. While it contains natural quartz, it is the manufacturing process and the addition of pigments that allow for an astonishing array of colors and patterns. From classic marble and granite looks to contemporary solid colors and unique abstract designs, engineered quartz can replicate the most sought-after natural stone appearances with remarkable fidelity, often surpassing them in consistency and uniformity. The resin binder not only holds the quartz crystals together but also contributes to its non-porous nature, a critical factor in its stain resistance. This inherent impermeability means that liquids like wine, coffee, or oil are unable to penetrate the surface, making it exceptionally hygienic and easy to maintain. The finish of quartz is typically polished, offering a sleek, reflective surface that adds a touch of luxury and sophistication to any environment.

The fundamental difference in their composition – acrylic polymer with mineral fillers versus natural quartz crystals with resin binders – sets the stage for their divergent performance characteristics. Acrylic’s inherent flexibility and thermoformability lend themselves to more organic and seamless designs, while quartz’s exceptional hardness and density offer unparalleled resilience against daily wear and tear. This introductory exploration into the genesis of these two remarkable materials is just the beginning of understanding how they can shape the spaces we inhabit, offering a spectrum of possibilities for both form and function. As we delve deeper, we will uncover the practical implications of these differences in areas such as durability, maintenance, cost, and their suitability for various applications, ultimately empowering you to make a choice that is as beautiful as it is practical.

The Art of Application – Choosing Your Surface Champion

Performance and Practicality – Where Acrylic and Quartz Shine

Having explored the foundational compositions of artificial acrylic stone and artificial quartz stone, we now venture into the practical arena – how these materials perform in real-world applications and what considerations are paramount when making your selection. The inherent differences in their make-up translate into distinct advantages and disadvantages, influencing everything from their resilience to heat and scratches to their aesthetic versatility and long-term value. Understanding these performance metrics is crucial for aligning your chosen surface with the demands of your lifestyle and the intended use of the space.

Let’s begin with durability, a cornerstone of any material destined for frequent use. Artificial quartz stone generally boasts superior hardness and resistance to scratches and impact. Composed of approximately 90-93% natural quartz, a mineral known for its exceptional strength, engineered quartz is remarkably tough. It can withstand the rigors of a busy kitchen, resisting nicks and cuts from knives (though using a cutting board is always recommended for longevity). Its density also contributes to its excellent stain resistance; spills of wine, oil, or acidic substances are unlikely to penetrate its non-porous surface, making clean-up a breeze. Furthermore, quartz exhibits good heat resistance, capable of withstanding moderately hot pots and pans placed directly on the surface for short periods. However, extreme and sudden temperature fluctuations, such as placing a very hot pan on a cold countertop, can potentially cause thermal shock and lead to cracking, so the use of trivets is advisable.

Artificial acrylic stone, while not as inherently hard as quartz, offers a different kind of resilience. Its strength lies in its flexibility and repairability. While it can be scratched or chipped more readily than quartz, these imperfections are often reversible. Minor scratches can be buffed out by hand with an abrasive cleaner and a soft cloth, or by a professional using specialized sanding techniques, restoring the surface to its original smooth finish. Deeper damage can also be repaired seamlessly, making it an ideal choice for areas prone to wear and tear where the ability to refresh the surface is a significant advantage. In terms of stain resistance, acrylic is also non-porous and thus highly resistant to most common household stains. However, it is more susceptible to damage from harsh chemicals or prolonged exposure to direct sunlight, which can cause discoloration over time. Its heat resistance is generally lower than quartz; direct contact with hot cookware can cause permanent scorching or melting, necessitating the consistent use of trivets or heat-resistant mats.

Aesthetics are, of course, a primary driver in material selection. Both acrylic and quartz offer an expansive palette of colors, patterns, and finishes. Artificial quartz excels in its ability to meticulously replicate the look of natural stones like granite and marble, often with a greater degree of consistency and uniformity than their natural counterparts. This means you can achieve the coveted look of exotic veining without the inherent variations, potential flaws, or porous nature of natural stone. The reflective, polished finish of quartz adds a sense of luxury and depth. Artificial acrylic stone, on the other hand, offers a unique advantage in its ability to be seamlessly fabricated and thermoformed. This opens up possibilities for innovative designs, such as integrated sinks, curved edges, and intricate sculptural elements that are simply not achievable with quartz. The subtle translucency of acrylic allows for a different kind of visual interest, and it can be manufactured in a vast spectrum of colors, from bold, vibrant hues to soft, pastel shades and sophisticated neutrals.

Maintenance is another crucial consideration for homeowners and designers. Both materials are generally low-maintenance due to their non-porous nature, which prevents the absorption of liquids and bacteria. For artificial quartz, daily cleaning typically involves wiping down the surface with a damp cloth and mild soap. For tougher stains, a non-abrasive cleaner can be used. Harsh chemicals, abrasive scouring pads, and excessive heat should be avoided to preserve its luster. Artificial acrylic stone also benefits from simple daily cleaning with soap and water. For more stubborn marks, a mild abrasive cleaner can be effective. It’s important to avoid harsh chemicals and extreme heat, as they can damage the surface. The key differentiator in maintenance lies in repairability; the ease with which acrylic can be restored to its original condition offers a unique long-term maintenance advantage for certain applications.

Cost is often a deciding factor, and it’s important to note that pricing can vary significantly based on brand, color, pattern complexity, and fabrication. Generally, artificial quartz stone tends to be in a similar or slightly higher price bracket than premium artificial acrylic stones, particularly for designs that mimic rare natural stones. However, the installation cost can also play a role. Acrylic’s ability to be shaped and fabricated with fewer seams, and its lighter weight, can sometimes lead to more straightforward installation.

In summary, the choice between artificial acrylic stone and artificial quartz stone hinges on a careful assessment of your priorities. If unparalleled hardness, scratch resistance, and the ability to replicate natural stone with exceptional consistency are paramount, artificial quartz emerges as a compelling choice. Its robust nature makes it a workhorse for busy kitchens and high-traffic areas. If design flexibility, the possibility of seamless, integrated elements, and the invaluable advantage of repairability are more important, then artificial acrylic stone offers a unique and adaptable solution. Its warmth to the touch and potential for innovative forms make it a favorite for those seeking both aesthetics and long-term recoverability. Both materials represent a significant leap forward in surface technology, offering beauty, durability, and a touch of modern elegance to transform any space into a true reflection of your vision.