The quest for the perfect countertop, vanity, or wall cladding can feel like navigating a labyrinth of material choices. In today’s design landscape, two contenders consistently rise to the top for their versatility, aesthetic appeal, and innovative applications: acrylic and solid surface. While often grouped together due to their similar appearances and non-porous nature, these materials, born from different manufacturing processes and boasting distinct properties, offer unique advantages and considerations for homeowners and designers alike. Understanding these differences is key to making an informed decision that not only elevates your space but also aligns with your lifestyle and budget.

Acrylic, often recognized by brand names like Corian® (though Corian® itself is a type of solid surface, the term acrylic is sometimes used loosely to refer to similar materials), is a thermosetting polymer. Its primary component is methyl methacrylate (MMA), which is polymerized with other acrylic monomers and fillers, most notably alumina trihydrate (ATH). This combination creates a material that is remarkably versatile, allowing for seamless integration, thermoforming into complex shapes, and a vast array of colors and patterns. The magic of acrylic lies in its ability to be manipulated. Unlike natural stone that must be cut and shaped, acrylic can be heated and molded, opening up a world of design possibilities that extend far beyond flat surfaces. Think of integrated sinks that appear to grow organically from the countertop, flowing waterfall edges, or even curved reception desks that become sculptural elements in a commercial space. This thermoformability is a significant differentiator, offering architects and designers a freedom rarely found with other solid materials.

The aesthetic appeal of acrylic is undeniable. Its smooth, matte finish can be incredibly sophisticated, providing a clean and modern look. It can mimic the appearance of natural stone, boasting intricate veining and subtle speckling, or it can come in bold, solid colors that make a statement. The seamless nature of acrylic installations is another major draw. Seams are virtually invisible, creating a continuous, hygienic surface that is ideal for kitchens, bathrooms, and healthcare settings where cleanliness is paramount. This lack of grout lines or visible joints means less opportunity for dirt and bacteria to accumulate, simplifying cleaning and maintenance. Furthermore, acrylic is known for its color consistency. Once a color is chosen, you can be assured that subsequent pieces will match perfectly, a significant advantage when extending a design or replacing a damaged section.

However, like any material, acrylic comes with its own set of considerations. While durable, it is not impervious to scratching or heat damage. Its softer nature compared to granite or quartz means that sharp objects can leave their mark if not used with care. trivets and cutting boards are your best friends when working with acrylic surfaces. High heat, such as from a hot pot or pan placed directly on the surface, can cause discoloration or even melting. This is a crucial point to remember for anyone considering acrylic for their kitchen countertops. While it can withstand everyday cooking temperatures, direct, prolonged exposure to extreme heat requires caution.

Another aspect to consider is its susceptibility to certain chemicals. While generally resistant to most household cleaners, strong solvents or abrasive cleaners can dull or damage the surface. Always check manufacturer recommendations for cleaning agents to ensure longevity and maintain the pristine appearance of your acrylic surfaces. The repairability of acrylic is a significant advantage, though. Minor scratches can often be buffed out with specialized polishing compounds, and deeper damage can be repaired by trained professionals, often making the surface look as good as new. This ability to be restored, rather than requiring a full replacement, can be a cost-effective solution over the long term.

The cost of acrylic can vary widely depending on the brand, color, complexity of the design, and the fabricator. While generally in a mid-to-high price range, its unique design flexibility and seamless integration can sometimes justify the investment, especially when considering the elimination of separate sink costs or complex edge profiles. The installation process also requires specialized skills and equipment due to its thermoforming capabilities and the need for precise seaming techniques. This means choosing a reputable and experienced fabricator is paramount to achieving a flawless result.

Moving on to solid surface, a material that shares many of acrylic’s desirable characteristics, it’s important to understand its composition. Solid surface is a man-made material composed primarily of acrylic polymers and alumina trihydrate (ATH), a mineral derived from bauxite ore. This composition is very similar to acrylic, and indeed, many solid surface materials are acrylic-based. However, the term “solid surface” is often used more broadly to encompass materials that may have different polymer binders, such as polyester or a hybrid of acrylic and polyester. The key differentiator often lies in the manufacturing process and the specific ratio of components, which can subtly influence the material’s properties.

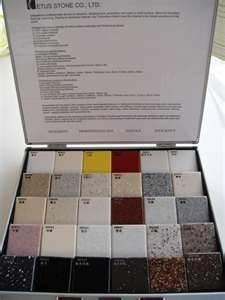

Like acrylic, solid surface is non-porous, meaning it does not absorb liquids, making it resistant to stains and bacteria. This hygienic quality makes it a popular choice for kitchens, bathrooms, laboratories, and healthcare facilities. The seamless appearance is also a hallmark of solid surface, allowing for integrated sinks and a fluid aesthetic. The ability to repair minor scratches and damage by buffing or sanding is another shared benefit, extending the lifespan of the material. The vast array of colors, patterns, and finishes available in solid surface is truly impressive, offering a design solution for virtually any aesthetic. From realistic stone replicas to vibrant, solid hues and even translucent options that can be backlit for dramatic effect, the design potential is immense.

The durability of solid surface is generally considered very good, offering a balance of toughness and workability. It’s less prone to chipping than some natural stones and can withstand the rigors of daily use in busy environments. The matte finish is standard, but many solid surface materials can also be polished to a high gloss, offering a different aesthetic. The lack of porosity also means that spills like wine, coffee, or juice are unlikely to leave stains, making cleanup a breeze.

However, similar to acrylic, direct contact with high heat can be a concern for solid surface. While it can tolerate moderate heat, placing extremely hot pots and pans directly onto the surface without protection can lead to heat marks or discoloration. This is a common characteristic of most composite surfacing materials and emphasizes the importance of using trivets and hot pads. Scratching is also a possibility, especially with darker or high-gloss finishes, which tend to show imperfections more readily. Regular maintenance with mild soap and water is usually sufficient, but for tougher stains, specific cleaning agents recommended by the manufacturer should be used. Avoid abrasive cleaners and scouring pads, as these can scratch and dull the surface.

The fabrication and installation of solid surface require skilled professionals. While it can be cut and shaped with woodworking tools, the precise seaming and finishing to achieve that coveted seamless look demands expertise. The cost of solid surface is comparable to acrylic, often falling within a similar mid-to-high price bracket, depending on the brand, design, and complexity of the installation. The investment is often justified by its aesthetic appeal, hygiene, and longevity.

When embarking on a renovation or building project, the choice of surfacing materials can significantly impact both the aesthetic and functional outcomes. Acrylic and solid surface, two modern marvels in the world of interior design, offer compelling solutions for a wide range of applications, from kitchen countertops and bathroom vanities to wall panels and custom furniture. While they share many desirable traits – namely their non-porous nature, seamless integration capabilities, and vast aesthetic versatility – a closer examination reveals nuanced differences that can guide you towards the optimal choice for your specific needs.

Let’s delve deeper into the practicalities of living with acrylic. Its inherent thermoformability is a game-changer for bespoke designs. Imagine a kitchen island with a perfectly integrated sink that flows seamlessly from the countertop, eliminating those pesky crevices where grime can hide. Or perhaps a uniquely shaped reception desk for a commercial space that becomes a true statement piece. This ability to be molded into almost any conceivable shape opens up a universe of creative possibilities that are simply not achievable with traditional materials like stone or laminate. The consistency in color is another significant advantage. If a section of your acrylic countertop is ever damaged, sourcing an exact color match for repair or extension is straightforward, ensuring a cohesive look throughout your space.

However, it’s crucial to address the concerns surrounding acrylic’s resilience. While it’s durable for everyday use, its relative softness means it’s more susceptible to scratches than materials like quartz or granite. This isn’t to say it’s fragile; with mindful use – employing cutting boards and trivets religiously – it can maintain its pristine appearance for years. The key is understanding its limitations. Direct, prolonged exposure to high heat is the Achilles’ heel of many acrylic-based surfaces. A hot pan fresh off the stove can cause thermal shock, leading to discoloration or even irreparable damage. Therefore, a commitment to using protective measures is non-negotiable for those who opt for acrylic in high-heat areas like kitchens. Similarly, while resistant to most common household cleaners, certain harsh chemicals or abrasive cleaning pads can dull the finish or even cause etching. Regular maintenance with mild soap and water, coupled with manufacturer-approved cleaning solutions for tougher spots, will ensure its longevity.

The repairability of acrylic is a significant plus point that often gets overlooked. Minor surface scratches can often be buffed out by a homeowner with a specialized polishing kit. For more significant damage, professional restoration is usually possible, making it a material that can be rejuvenated rather than requiring a costly replacement. This aspect contributes to its long-term value, especially in high-traffic environments. The cost of acrylic can vary. Entry-level acrylics might be more budget-friendly, while high-end, custom-designed pieces with complex thermoforming can represent a significant investment. The cost of professional installation, which is essential for achieving seamless joints and complex forms, also needs to be factored in.

Now, let’s turn our attention back to solid surface, a material that often blurs the lines with acrylic due to its similar composition and performance. The primary difference, as mentioned, often lies in the specific resin binders used and the manufacturing process, which can subtly influence properties like hardness and heat resistance, though the differences are often marginal for typical residential use. The non-porous quality of solid surface is a standout feature, making it exceptionally hygienic. This characteristic is invaluable in environments where cleanliness is paramount, such as kitchens, bathrooms, and even commercial food preparation areas. Spills are easily wiped up, and the material doesn’t harbor bacteria or mold, contributing to a healthier living or working space.

The aesthetic possibilities with solid surface are virtually limitless. Manufacturers offer an astounding spectrum of colors, from subtle, natural-looking patterns that mimic granite or marble to bold, vibrant hues that can inject personality into any design. There are even translucent options that can be backlit, creating a dramatic and sophisticated ambiance – think of a bar top or a feature wall that glows with an inner light. The ability to achieve seamless joints is a shared advantage with acrylic. This means integrated sinks, where the sink basin is formed as one continuous piece with the countertop, are a popular and practical choice. This eliminates the unsightly and unhygienic gap often found between a separate sink and countertop, simplifying cleaning and lending a sleek, modern look.

When it comes to durability, solid surface strikes a good balance. It’s generally considered tougher than acrylic, offering a bit more resistance to scratches and everyday wear and tear. However, it’s important to reiterate that direct contact with extreme heat is still a point of caution. While it can handle the warmth of everyday cooking, placing scorching hot pots and pans directly on the surface without a trivet is ill-advised and can lead to heat damage. Similarly, while it’s robust, sharp objects can still cause scratches, especially on darker or highly polished finishes. Routine cleaning with mild soap and water is generally sufficient for most daily messes. For more stubborn stains, specific cleaning agents recommended by the manufacturer should be employed, and abrasive materials should be avoided to preserve the surface integrity.

The repairability of solid surface is another strong suit. Minor scratches and scuffs can typically be sanded out and then polished to restore the original finish, a task that can often be undertaken by experienced homeowners or, more reliably, by professional fabricators. This capability for restoration significantly extends the material’s lifespan and preserves its aesthetic appeal. In terms of cost, solid surface generally falls into a similar price bracket as acrylic, making it a competitive option. The overall price will depend on the brand, the complexity of the design, the edge profiles chosen, and the intricacy of the installation. The specialized skills required for precise fabrication and seamless installation mean that engaging a reputable professional is crucial for achieving the best results.

In essence, the choice between acrylic and solid surface often comes down to subtle preferences and priorities. If extreme design flexibility, including complex curves and integrated elements, is paramount, and you are committed to rigorous heat protection, acrylic might edge out. If slightly greater resistance to daily wear and tear, coupled with an equally impressive range of aesthetics and seamless integration, is your focus, solid surface presents a compelling case. Both materials offer a modern, hygienic, and aesthetically pleasing alternative to traditional surfacing options, and with proper care and installation, they can transform your space into a testament to contemporary design and enduring functionality. The “picture and video gallery” you mentioned would undoubtedly showcase the myriad of ways these materials can be utilized, highlighting their seamless beauty and practical advantages. Ultimately, understanding these nuances empowers you to make a confident decision that will bring beauty and utility to your home for years to come.