Unveiling the Charm of Acrylic Solid Surface: More Than Just a Pretty Face

In the ever-evolving landscape of interior design and architectural materials, few have captured the imagination quite like acrylic solid surface. Often referred to by its broad classification as “artificial stone” or more specifically as a composite material, this innovative substance has transcended mere functionality to become a cornerstone of contemporary aesthetics. But what exactly is this material that graces everything from sleek kitchen countertops and elegant bathroom vanities to sophisticated commercial interiors and even critical healthcare environments? The answer lies in its unique composition and the remarkable properties it boasts, making it a truly transformative element in how we conceive and construct our living and working spaces.

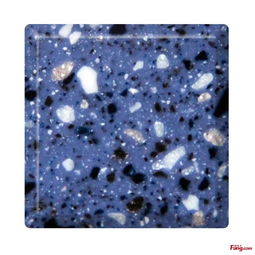

At its core, acrylic solid surface is a blend of natural minerals, acrylic polymers, and pigments. The primary mineral component is typically alumina trihydrate (ATH), a white powder derived from bauxite ore. This mineral filler provides bulk, strength, and fire-retardant qualities. The acrylic polymer, most commonly polymethyl methacrylate (PMMA), acts as the binder, creating a homogenous and durable matrix. Pigments are then added to achieve an almost limitless spectrum of colors and patterns, from solid hues that mimic the purity of alabaster to intricate veining that rivals natural stone. The magic of acrylic solid surface lies in its creation process: these ingredients are meticulously mixed and then cast into sheets or shapes under controlled conditions. This controlled manufacturing process is key to its consistent quality and the absence of voids or pores, a characteristic that sets it apart from many traditional materials.

One of the most celebrated attributes of acrylic solid surface is its non-porous nature. Unlike natural stone such as granite or marble, which can absorb liquids and harbor bacteria, acrylic solid surface presents an impenetrable barrier. This inherent resistance to moisture and stains makes it an ideal choice for high-traffic areas prone to spills, such as kitchens and bathrooms. Food particles, grease, and colored liquids simply sit on the surface, easily wiped away without leaving a trace or a lingering odor. This hygienic quality is not just a matter of convenience; it has significant implications for public health, making acrylic solid surface a preferred material in hospitals, laboratories, and food service establishments where sanitation is paramount. The seamless integration of sinks and countertops, achieved through specialized adhesives that chemically bond the material, further enhances its hygiene. This eliminates grout lines and crevices where dirt and microbes could otherwise accumulate, creating a truly monolithic and easy-to-clean surface.

Beyond its hygienic advantages, the aesthetic flexibility of acrylic solid surface is a significant draw for designers and homeowners alike. The ability to produce it in a vast array of colors, including custom matches, allows for unparalleled creative freedom. Whether you envision a minimalist white oasis, a dramatic black statement piece, or a vibrant hue to energize a space, acrylic solid surface can deliver. Furthermore, its translucency in certain formulations opens up fascinating possibilities for backlighting, creating ethereal glows that add depth and ambiance to furniture, reception desks, and decorative features. The material can also be manipulated to mimic the appearance of natural stone, wood, or even concrete, offering a cost-effective and more durable alternative without compromising on visual appeal. This chameleon-like quality ensures that acrylic solid surface can seamlessly integrate into any design style, from ultra-modern to classic traditional.

The practical benefits extend to its remarkable durability and repairability. While not impervious to scratches or chips, acrylic solid surface is designed to withstand the rigors of daily use. Its homogenous composition means that color and pattern permeate the entire thickness of the material, so minor damage doesn’t reveal a different colored core. More importantly, this damage is often repairable. Scratches can be buffed out, and even more significant chips or cracks can be expertly repaired by trained professionals, often making the surface look as good as new. This longevity and ability to be restored to its original condition contribute to its long-term value and sustainability, reducing the need for premature replacement. This inherent resilience, combined with its captivating aesthetics and superior hygiene, positions acrylic solid surface as a truly remarkable material that continues to redefine the possibilities in design.

The Transformative Power of Acrylic Solid Surface: From Concept to Creation

Building upon its inherent strengths, acrylic solid surface truly shines in its ability to be shaped and transformed, offering a level of design flexibility that few other materials can match. This malleability is a direct result of its composite nature and the way it’s manufactured, allowing it to be thermoformed and seamlessly joined, unlocking a world of creative potential that moves far beyond the limitations of traditional rigid materials.

One of the most astonishing capabilities of acrylic solid surface is its thermoformability. When heated to specific temperatures, the material becomes pliable and can be molded into virtually any shape – curves, waves, intricate three-dimensional forms, and even complex organic designs. This opens up a universe of possibilities for designers seeking to break free from straight lines and right angles. Imagine a reception desk that elegantly flows like a sculpted wave, a waterfall countertop that cascades seamlessly to the floor, or a bespoke bathtub that cradles the user in ergonomic comfort. These are not mere fanciful ideas; they are tangible realities made possible by the thermoforming of acrylic solid surface. This process allows for the creation of visually stunning and highly functional pieces that are entirely unique, transforming ordinary spaces into extraordinary experiences. Architects and designers can push the boundaries of form and function, creating bespoke elements that are not only beautiful but also perfectly tailored to their intended use and environment.

The seamless integration capabilities of acrylic solid surface are equally impressive. As mentioned earlier, specialized adhesives create a chemical bond between pieces of the material, effectively fusing them together to create a single, unbroken surface. This is particularly revolutionary for applications like countertops and sinks. Unlike traditional materials where a sink might be undermounted or drop-in, creating visible seams and potential collection points for dirt, acrylic solid surface sinks can be seamlessly integrated into the countertop. This results in a smooth, continuous surface that is not only aesthetically pleasing but also incredibly hygienic and easy to clean. This seamlessness extends to joining different colors or patterns, allowing for intricate inlays, logos, or decorative patterns to be incorporated directly into the surface. It allows for the creation of large, monolithic surfaces without visible joints, which is particularly advantageous in commercial settings or for creating a sense of expansive elegance in residential spaces.

The applications of acrylic solid surface are as diverse as the designs it can achieve. In the kitchen, it’s a natural choice for countertops, backsplashes, and integrated sinks, offering a beautiful, durable, and hygienic surface for food preparation and gathering. Bathrooms benefit from its resistance to moisture and stains, making it ideal for vanities, shower walls, and bathtubs that are both elegant and practical. Beyond these core residential uses, acrylic solid surface has become a material of choice in a multitude of commercial and public spaces. Its ability to be fabricated into unique shapes and its hygienic properties make it perfect for bar tops, restaurant tables, retail displays, and reception desks that need to withstand heavy use while maintaining a high-end appearance.

In the healthcare sector, the non-porous and seamless nature of acrylic solid surface is a critical advantage. It is frequently used for laboratory benchtops, nurses’ stations, surgical prep areas, and patient room surfaces, where maintaining sterile environments is of utmost importance. Its resistance to chemicals and disinfectants, coupled with its ease of cleaning, helps to prevent the spread of infections. Furthermore, its ability to be repaired means that even in demanding environments, surfaces can be maintained and restored, extending their lifespan and ensuring continued performance.

The growing emphasis on sustainability also sees acrylic solid surface in a favorable light. While its production involves chemical processes, many manufacturers are committed to creating materials with lower environmental impact, utilizing recycled content and energy-efficient manufacturing. Its exceptional durability and repairability mean that it has a long service life, reducing the need for frequent replacement and thereby minimizing waste. When it does eventually reach the end of its life, some formulations can be recycled. This combination of longevity, repairability, and potential for recycled content makes it a more sustainable option compared to materials that require frequent replacement or are difficult to maintain. In essence, acrylic solid surface is not just a material; it’s a testament to innovation, offering a blend of beauty, performance, and adaptability that continues to shape the way we design and interact with our built environments.