The seamless beauty and unparalleled versatility of acrylic solid surface have revolutionized the way we think about interior and exterior design. It’s a material that whispers sophistication while shouting durability, a seemingly magical concoction that can be molded, shaped, and integrated into virtually any architectural vision. At the heart of this material’s widespread adoption and continued innovation lie the dedicated and highly skilled “亚克力人造石生产厂家” – the acrylic solid surface manufacturers. These aren’t just factories churning out products; they are centers of advanced material science, design ingenuity, and meticulous craftsmanship.

The journey of acrylic solid surface from raw components to finished slabs is a fascinating blend of chemistry and precision engineering. At its core, acrylic solid surface is typically composed of acrylic polymers (like PMMA), natural minerals (primarily alumina trihydrate – ATH), and pigments. ATH, derived from bauxite ore, acts as a filler, providing fire-retardant properties and contributing to the material’s density and durability. The acrylic resin acts as the binder, granting the material its plasticity, non-porosity, and resistance to stains and chemicals. The careful selection and precise proportioning of these ingredients are the first steps in a complex manufacturing process.

“亚克力人造石生产厂家” employ sophisticated chemical processes to create a homogenous mixture. This slurry is then typically poured into molds or cast onto a continuous production line. The casting process is critical for achieving the desired sheet thickness and ensuring uniformity. For cast sheets, the mixture is carefully controlled for viscosity and temperature as it’s poured, often onto a moving belt. This is followed by a curing phase, where the material hardens. This curing process can involve heat and time, meticulously managed to ensure optimal molecular bonding and structural integrity.

One of the defining characteristics of acrylic solid surface, and a testament to the manufacturing prowess of “亚克力人造石生产厂家,” is its non-porous nature. This is achieved through the dense, homogenous structure created during the casting and curing. Unlike natural stone or even some engineered quartz, solid surface doesn’t have microscopic pores that can absorb liquids, harbor bacteria, or lead to staining. This inherent cleanliness makes it an exceptionally hygienic material, a key reason for its prevalence in healthcare settings, laboratories, and kitchens. Manufacturers achieve this by carefully controlling the curing process to eliminate any voids or inconsistencies within the material matrix.

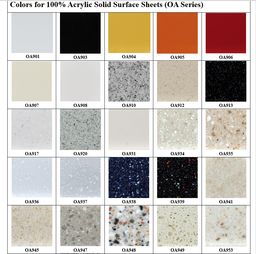

The aesthetic possibilities of acrylic solid surface are virtually limitless, and this is where the artistry of “亚克力人造石生产厂家” truly shines. Through the judicious use of pigments, manufacturers can create an astonishing array of colors, from pure whites and deep blacks to vibrant hues and subtle earth tones. Beyond solid colors, sophisticated manufacturing techniques allow for the incorporation of veining, particulate effects, and even translucency. This means solid surface can mimic the look of natural marble, granite, or even concrete, while offering superior performance characteristics. The development of these complex patterns involves intricate control over pigment dispersion and the introduction of various additives during the mixing stage, followed by precise execution during casting to ensure these patterns are integrated seamlessly throughout the material’s thickness.

Furthermore, the ability to create large, seamless panels is a hallmark of high-quality acrylic solid surface. “亚克力人造石生产厂家” invest in advanced casting and finishing technologies that allow for the production of sheets with minimal thermal expansion and contraction, and remarkably precise dimensions. This minimizes the need for unsightly seams in installations, particularly in countertops and wall claddings, contributing to a cleaner, more streamlined aesthetic and preventing the accumulation of dirt and moisture at joint lines. The finishing processes, including sanding and polishing, are equally critical, transforming the raw cast sheet into a smooth, tactile, and visually appealing surface ready for fabrication.

The commitment to quality control is paramount for “亚克力人造石生产厂家.” From the sourcing of raw materials to the final inspection of finished sheets, every stage is monitored to ensure consistency and adherence to stringent performance standards. This includes testing for impact resistance, thermal shock resistance, UV stability, and chemical resistance. Manufacturers often adhere to international standards and certifications, providing customers with the assurance that the product they are receiving meets rigorous benchmarks for durability and safety. This dedication to quality ensures that the end-user receives a product that not only looks beautiful but also performs exceptionally well over its intended lifespan.

The innovation doesn’t stop at the material level. “亚克力人造石生产厂家” are also at the forefront of developing new product lines and improving existing ones. This might involve creating formulations with enhanced UV resistance for outdoor applications, developing fire-retardant grades for specific building codes, or engineering surfaces with antimicrobial properties. Their research and development departments are constantly exploring new pigment technologies, binder formulations, and processing techniques to push the boundaries of what is possible with acrylic solid surface. This continuous pursuit of improvement ensures that acrylic solid surface remains a leading choice for designers and architects seeking cutting-edge material solutions.

In essence, the expertise of “亚克力人造石生产厂家” lies in their ability to harmonize advanced material science with an acute understanding of design and application. They are the silent architects of countless beautiful and functional spaces, transforming raw elements into surfaces that inspire, endure, and elevate the everyday. Their dedication to precision, innovation, and quality makes acrylic solid surface not just a building material, but a canvas for creativity and a testament to modern manufacturing excellence.

The influence of “亚克力人造石生产厂家” extends far beyond the factory floor, permeating the very fabric of our built environments. The versatility of acrylic solid surface allows it to transcend traditional material limitations, finding its way into an astonishing array of applications, from the most demanding healthcare settings to the most opulent residential kitchens, and even into the realm of public art. This adaptability is a direct result of the sophisticated manufacturing processes and the inherent properties engineered into the material by these specialized producers.

Consider the culinary world, where hygiene and durability are non-negotiable. Countertops, backsplashes, and even integrated sinks crafted from acrylic solid surface are a common sight. The seamless nature of fabrication means that joints, often weak points for bacterial growth and staining in other materials, are virtually eliminated. “亚克力人造石生产厂家” produce sheets that can be thermoformed – heated and bent into curves and complex shapes. This allows for the creation of coved backsplashes that flow directly into the countertop, eliminating the difficult-to-clean gap behind the sink. The non-porous surface means spills from coffee, wine, or acidic foods can be wiped away without leaving a trace or a permanent mark, a significant advantage over porous natural stones or laminates. Furthermore, minor scratches or scuffs, which can occur with heavy use, can often be repaired by sanding and polishing, restoring the surface to its original pristine condition – a testament to the material’s inherent resilience and the manufacturer’s commitment to creating a repairable product.

In the healthcare sector, the demands are even more extreme. Hospitals, clinics, and laboratories require surfaces that can withstand aggressive cleaning agents, resist staining from bodily fluids and chemicals, and provide an inherently sterile environment. Acrylic solid surface, manufactured by “亚克力人造石生产厂家” to exacting standards, excels in these areas. Its non-porous nature prevents the absorption of pathogens, and its resistance to a wide range of disinfectants ensures that it can be thoroughly sanitized without degradation. The ability to create monolithic surfaces – such as integrated sinks and seamless wall panels – further minimizes the potential for microbial colonization. Many manufacturers offer specific formulations that may incorporate antimicrobial additives, providing an additional layer of protection in these critical environments. The consistency and reliability of these materials are vital, and the rigorous quality control employed by leading “亚克力人造石生产厂家” provides the necessary assurance for such sensitive applications.

The architectural and design possibilities are equally compelling. “亚克力人造石生产厂家” supply materials that empower architects and designers to push creative boundaries. The translucency of certain solid surface formulations opens up unique lighting design opportunities. When backlit, these materials can emit a soft, ethereal glow, transforming walls, reception desks, and bar tops into captivating focal points. The ability to thermoform the material means that designers are not limited by flat planes. They can create sweeping curves, organic shapes, and bespoke furniture pieces that would be impossible or prohibitively expensive with traditional materials. Imagine a reception desk that flows like a wave, or a retail display unit with intricate, sculpted forms – these are the design canvases that acrylic solid surface provides.

Beyond countertops and wall cladding, the applications multiply. In the marine industry, its lightweight and durable nature makes it ideal for galleys and bathrooms on yachts and cruise ships. In the hospitality sector, it’s used for hotel reception desks, bar tops, and bathroom vanities, where both aesthetics and resilience are key. Even in retail environments, custom-designed displays, fitting rooms, and checkout counters benefit from its ability to be shaped and branded with unique colors and logos. “亚克力人造石生产厂家” often collaborate with designers and fabricators, offering technical support and product development services to bring complex visions to life. This collaborative approach ensures that the material’s potential is fully realized in every project.

The environmental aspect of acrylic solid surface is also increasingly important, and “亚克力人造石生产厂家” are responding to this. Many manufacturers are focused on producing materials with lower volatile organic compound (VOC) emissions, contributing to healthier indoor air quality. The longevity and repairability of solid surface also contribute to its sustainability credentials, as it often outlasts other countertop materials and can be refurbished rather than replaced, reducing waste. Some companies are also exploring the use of recycled content in their formulations or implementing more energy-efficient manufacturing processes. This growing commitment to sustainability aligns with the broader trends in green building and responsible manufacturing.

The global reach of “亚克力人造石生产厂家” is a testament to the universal appeal and proven performance of acrylic solid surface. Whether it’s a local café in London, a hospital in Tokyo, or a luxury hotel in Dubai, the chances are that sophisticated, durable, and beautiful surfaces are made possible by the innovation and dedication of these specialized manufacturers. They are not just producing a material; they are providing solutions that enhance our living and working spaces, offering a blend of form, function, and enduring quality that is hard to match. The continuous investment in research and development, coupled with a deep understanding of market needs, ensures that acrylic solid surface will remain a cornerstone of modern design for years to come. Their role is indispensable in shaping the aesthetic and functional landscape of our world.