In the ever-evolving landscape of interior design and material innovation, two contenders consistently vie for the spotlight when it comes to creating seamless, stylish, and functional surfaces: acrylic and solid surface. Often mentioned in the same breath, these man-made marvels offer a wealth of design possibilities, but they are far from identical. Understanding their nuanced differences is key to unlocking their full potential and ensuring your design choices are not just aesthetically pleasing, but also practically sound. This exploration will delve deep into the very essence of acrylic and solid surface, dissecting their compositions, manufacturing processes, and inherent characteristics to illuminate what makes each one unique.

At its core, acrylic, often referred to by brand names like Corian® (though Corian is a specific brand of solid surface, it’s often used generically), is a polymer resin. Specifically, it’s a type of thermoplastic known as polymethyl methacrylate (PMMA). This clear, strong plastic is incredibly versatile, and its transparency can be a significant advantage. When acrylic is used for surfaces like countertops or wall panels, it’s typically a cast acrylic sheet that has been infused with pigments, fillers, and other additives to achieve a desired color, pattern, or opacity. The result is a material that can mimic the look of natural stone, wood, or even create entirely unique, avant-garde finishes. One of acrylic’s most defining characteristics is its ability to be thermoformed. This means that under controlled heat, acrylic can be bent, curved, and shaped into virtually any form imaginable. This malleability opens up a world of design freedom, allowing for intricate curves, waterfall edges, and integrated sinks that appear to flow seamlessly from the countertop itself. Think of a reception desk that sweeps in a graceful arc, or a bathroom vanity with a sink that’s not just integrated but part of the very material that forms the surface. This inherent design flexibility is a major draw for architects and designers seeking to push creative boundaries.

Solid surface, on the other hand, is a composite material. While it shares some similarities with acrylic in its end-use and aesthetic goals, its composition is fundamentally different. The most common type of solid surface is a blend of natural minerals (primarily aluminum trihydrate, a derivative of bauxite ore) and acrylic polymers. These components are mixed together with pigments and binders, then cast into sheets or molded into specific shapes. The presence of these mineral fillers gives solid surface a more substantial, stone-like feel and often a greater degree of hardness and scratch resistance compared to pure acrylic. While solid surface can also be thermoformed to a degree, its capabilities in this area are generally more limited than those of pure acrylic. The mineral content makes it less pliable under heat, meaning complex curves and sharp bends are more challenging to achieve, and may require specialized techniques or might not be feasible at all. However, this composition also contributes to its excellent durability and resistance to staining and impact. The way these materials are fabricated also plays a significant role in their perceived quality and seamlessness. Both acrylic and solid surface are known for their ability to be joined with adhesives that create virtually invisible seams. This is a game-changer in design, as it eliminates the unsightly grout lines and visible joints often associated with materials like tile or laminate. The result is a continuous, monolithic appearance that is both hygienic and aesthetically sophisticated. However, the precise method of achieving these seamless joints and the ultimate strength and invisibility of those seams can vary depending on the specific formulation of the acrylic or solid surface material being used. For instance, some solid surfaces may require more meticulous preparation and specialized adhesive matching to achieve the most discreet bond.

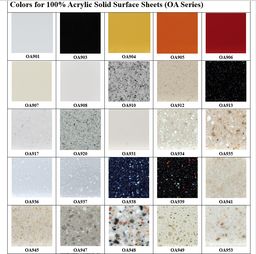

When we talk about aesthetics, both materials offer a vast palette. Acrylic can achieve incredibly vibrant and translucent colors that solid surface often cannot replicate. Imagine a countertop that glows from within when backlit, or a translucent blue that evokes the depths of the ocean. These effects are more readily achievable with acrylic due to its inherent clarity. Solid surface, while capable of a wide range of colors and patterns, often leans towards more naturalistic or sophisticated solid tones and veining that mimic natural stone. However, the realism of these patterns in solid surface can be quite impressive, offering a consistent and predictable aesthetic that can be a significant advantage in large-scale projects where natural stone might have unpredictable variations. The surface finish is another point of distinction. Acrylic typically has a naturally high gloss, though it can be honed to a matte or satin finish. Solid surface, while also often produced with a gloss finish, can also be readily buffed to a matte or satin sheen, and this finish can sometimes be more resistant to showing minor scratches or dullness over time compared to a high-gloss acrylic. Ultimately, the choice between acrylic and solid surface, from a purely visual standpoint, comes down to the desired effect. Do you want the vibrant, almost ethereal quality of translucent color and extreme formability, or the more grounded, subtly luxurious feel of a composite that emulates natural stone with exceptional consistency? This is where the deep dive into their material properties begins to inform the creative choices, laying the groundwork for understanding their performance in real-world applications.

Continuing our exploration into the fascinating world of acrylic and solid surface, we now shift our focus from their fundamental composition and aesthetic potential to their practical performance, durability, and maintenance. These are the aspects that truly dictate how a material will fare in the daily crucible of a kitchen, bathroom, or commercial space. Understanding these nuances will help you choose the material that not only looks spectacular but also stands the test of time and usage.

One of the most significant performance differences lies in their resistance to heat. Acrylic, being a thermoplastic, is generally more susceptible to heat damage than solid surface. While it can withstand typical kitchen temperatures, placing extremely hot pots or pans directly onto an acrylic surface without a trivet can lead to scorching, discoloration, or even melting. This means that users of acrylic surfaces need to be more diligent about using protective measures. Solid surface, with its mineral filler content, generally exhibits a higher degree of heat resistance. While it’s still advisable to use trivets for very hot items, solid surface is more forgiving of accidental contact with moderately hot cookware. This makes it a more robust choice for busy kitchens where convenience and resilience are paramount.

Scratch resistance is another crucial factor. Acrylic, especially in its more transparent or lighter-colored forms, can be more prone to visible scratching from knives, abrasive cleaners, or rough handling. While minor scratches on acrylic can often be buffed out or even repaired through sanding and polishing (a testament to its homogenous nature), deeper gouges can be more problematic. Solid surface, due to its harder composition with mineral fillers, generally offers better resistance to everyday scratches. However, it’s important to note that no surface is entirely scratch-proof. Aggressive scraping or dragging of heavy objects can still mar both materials. The advantage with solid surface often lies in the fact that its patterns and colors can be more adept at camouflaging minor surface imperfections, making small scratches less visually apparent than on a uniform, high-gloss acrylic surface.

When it comes to stain resistance, both materials excel, a significant advantage they hold over many natural materials like granite or marble, and even some engineered stones. Because both acrylic and solid surface are non-porous, liquids like wine, coffee, or oil cannot penetrate the surface and cause permanent stains. This inherent non-porosity also makes them highly hygienic, as bacteria and mold have no place to take root. However, the specific types of stains and the speed at which they can be wiped away might differ subtly. Certain pigments or chemicals might have a slightly greater affinity for one material over the other, though in most typical scenarios, both perform admirably. Prompt cleanup of spills is always recommended for both.

The repairability of these materials is a key consideration for long-term investment. As mentioned, acrylic’s homogenous nature means that scratches, minor chips, and even cigarette burns can often be repaired by a skilled technician through sanding and polishing, effectively restoring the surface to its original condition. This is a significant benefit for maintaining the pristine appearance of acrylic over many years. Solid surface also boasts excellent repairability. Chips, cracks, and even deep scratches can typically be filled and blended, and the surface can be re-finished to match the surrounding area. The seamlessness achieved in solid surface repairs can be as impressive as the original fabrication, making it a highly sustainable and long-lasting choice. The key is to engage qualified professionals for any significant repairs to ensure the integrity and aesthetic of the material are preserved.

Installation and fabrication offer another set of distinctions. Acrylic sheets are generally lighter and easier to cut and work with than solid surface, which can translate to potentially lower fabrication costs in some instances. However, acrylic’s greater flexibility under heat also means that complex, custom shapes require specialized equipment and expertise for thermoforming. Solid surface fabrication often involves precise cutting, routing, and adhesive bonding, requiring skilled craftspeople to achieve those signature seamless joints and integrated features. The ease with which solid surface can be cut into intricate designs or have edge profiles routered adds to its versatility in certain applications.

In terms of environmental impact, both materials are manufactured products and have an associated production footprint. Acrylic, being a petroleum-based product, relies on fossil fuels. However, advancements in recycling and the development of more sustainable manufacturing processes are continually being explored within the acrylic industry. Solid surface, with its significant mineral content derived from natural ore, also has an environmental impact associated with mining and processing. However, many solid surface manufacturers emphasize the use of recycled content and focus on durable products that extend the lifespan of installations, thereby reducing the need for frequent replacement. Both materials can contribute to healthier indoor environments due to their non-porous and VOC-free nature once installed.

Ultimately, the choice between acrylic and solid surface hinges on a careful balance of aesthetic aspirations, functional requirements, and budgetary considerations. If your design vision calls for vibrant, translucent colors, dramatic curves, and a material that can be shaped into almost any form, acrylic might be your ideal canvas. Its lighter weight and ease of cutting can also be advantageous for certain projects. If, however, your priority is a material that offers exceptional durability, a more stone-like feel, superior heat and scratch resistance for high-traffic areas, and a consistently sophisticated aesthetic that mimics natural stone, solid surface presents a compelling case. Both materials offer the unparalleled advantage of seamless integration and hygienic, easy-to-maintain surfaces, elevating the functionality and beauty of any space they inhabit. By understanding these fundamental differences, you are empowered to select the material that will best translate your design dreams into a tangible, beautiful, and enduring reality.