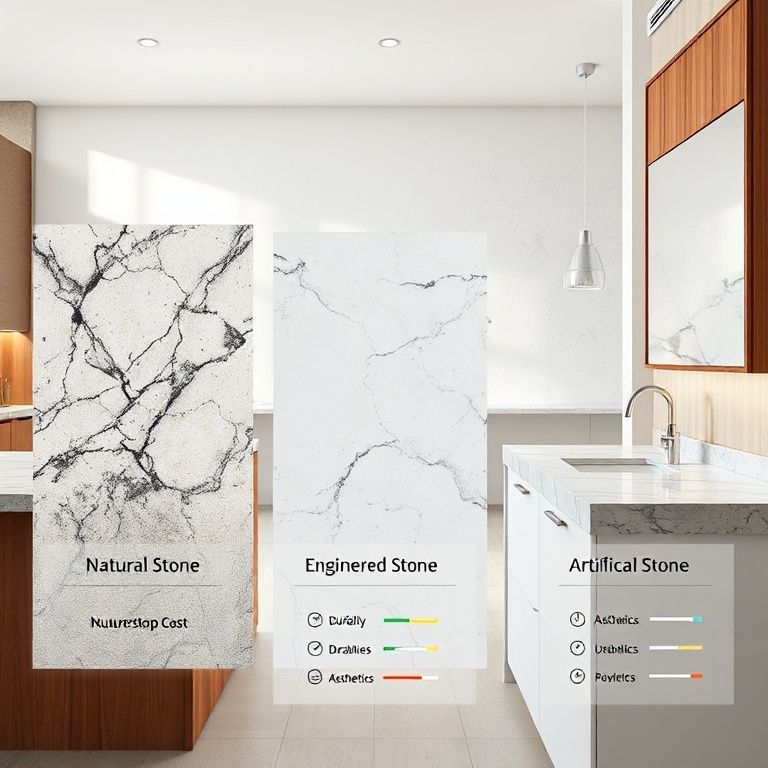

The whisper of a granite countertop, the cool, smooth touch of marble underfoot, the rugged, earthy embrace of slate – natural stone has captivated human design for millennia. It speaks of geological time, of forces shaping our planet, and imbues spaces with an unparalleled sense of authenticity and luxury. But in the modern design landscape, a formidable contender has emerged: engineered stone, also known as artificial stone. This man-made marvel, born from technological innovation, mimics the beauty of its natural counterpart while often touting enhanced performance and a different economic proposition. The age-old question then arises, and it’s one that echoes through countless renovation projects and architectural blueprints: “人造石和天然石材哪个贵?” – Which is more expensive, artificial stone or natural stone?

To truly unravel this question, we must first appreciate the inherent value and the intricate cost structures that define each material. Natural stone, a product of the earth’s slow, deliberate processes, carries a price tag influenced by a complex interplay of factors. The rarity and accessibility of a particular stone are primary drivers. Think of the exquisite, almost otherworldly beauty of rare marbles like Calacatta Gold, quarried from limited veins in Italy. Its scarcity, coupled with the demanding extraction process, places it at the pinnacle of the price spectrum. Conversely, more common granites, abundant in quarries worldwide, tend to be more budget-friendly. The journey from quarry to kitchen slab is also a significant cost determinant. Extraction itself requires heavy machinery, skilled labor, and often specialized techniques to minimize waste and ensure the integrity of the stone. Transportation, especially for massive slabs shipped across continents, adds considerable expense due to weight and fragility.

Then comes the processing. Once quarried, blocks of natural stone are cut into slabs, a process that demands precision and specialized diamond-bladed saws. The polishing, honing, or other finishing techniques applied to the surface further contribute to the final cost. A high-gloss polish on a marble slab, for instance, requires more meticulous attention and time than a brushed finish on a granite. The unique veining and patterns within a slab also play a role. A stone with particularly striking or rare patterns might command a higher price because each piece is, in essence, a singular work of art. Slab selection, too, can impact the budget. Clients often choose specific slabs at the fabrication stage, and if a particular piece has exceptional beauty or flawlessness, it will naturally be priced accordingly.

Furthermore, the installation of natural stone involves a level of expertise and care that translates into labor costs. Skilled installers are needed to handle the heavy, often brittle material, ensuring proper support, precise cuts for sinks and cooktops, and a seamless finish. The inherent porosity of some natural stones, like marble and some granites, also necessitates sealing to protect against stains and etching. While the sealing process itself is relatively inexpensive, it’s an additional step that contributes to the overall investment. The aesthetic imperfections that can occur with natural stone – subtle color variations, mineral inclusions, or even minor fissures – are often seen as part of its charm, its unique fingerprint. However, for those seeking absolute uniformity, these variations might necessitate selecting more expensive, higher-grade material or accepting a slightly higher risk of subtle aesthetic discrepancies.

Engineered stone, on the other hand, represents a triumph of human ingenuity. It’s a category that encompasses a variety of materials, most notably quartz surfaces. These are created by combining natural quartz crystals (typically around 90-95%) with polymer resins and pigments. This manufacturing process allows for remarkable control over the final product’s appearance, consistency, and performance. Because quartz is one of the hardest minerals found on Earth, engineered quartz surfaces inherit exceptional durability. The resins bind the quartz particles together, creating a non-porous, highly resistant surface. This non-porous nature is a significant advantage, as it means engineered stone is inherently resistant to staining, etching, and bacteria growth, often eliminating the need for regular sealing that natural stone requires.

The cost of engineered stone is influenced by different variables. The primary factor is the manufacturing process itself. Producing these slabs involves sophisticated machinery, precise blending of raw materials, and controlled curing processes. The quality and type of resins used, the fineness of the quartz crystals, and the complexity of the coloration and veining patterns all contribute to the manufacturing cost. While quartz itself is an abundant mineral, the energy and technology required to transform it into a finished slab are substantial. However, the controlled production environment allows for greater efficiency and less material waste compared to quarrying natural stone. This can lead to a more predictable cost per square foot for engineered stone, especially for popular designs.

The aesthetic range of engineered stone is vast, offering designers and homeowners an almost limitless palette of colors, patterns, and finishes. From the stark white of pure quartz to sophisticated marble imitations with realistic veining, engineered stone can replicate the look of natural stone with remarkable fidelity, or create entirely new, contemporary aesthetics. The consistency of engineered stone is a major selling point. Unlike natural stone, where each slab is unique, engineered stone slabs from the same production run will have virtually identical patterns and colors. This predictability can be a significant advantage during the design and installation phases, reducing the likelihood of costly surprises or the need for extensive slab matching. This consistency, coupled with the controlled manufacturing, often allows engineered stone to fall into a mid-range price bracket, offering a compelling balance of beauty and affordability.

However, it’s crucial to avoid generalizations. The “expensive” label is not a blanket statement for either category. A rare, high-grade natural marble will undoubtedly be more costly than a standard, widely available quartz. Conversely, a high-end, custom-designed engineered stone with intricate veining and metallic flecks could easily surpass the price of a common granite. The market is nuanced, and understanding the specific characteristics and origins of each material is key to discerning its true value and cost.

Continuing our exploration into the cost dichotomy between natural and engineered stones, it’s imperative to delve deeper into the long-term value proposition and the aesthetic nuances that influence purchasing decisions. While the initial outlay is a primary concern, the enduring beauty, maintenance requirements, and potential for repair significantly impact the overall cost of ownership.

Natural stone, with its inherent variations and unique geological story, often carries a higher perceived value. The “wow” factor of a genuine marble waterfall island or a slate feature wall is undeniable. This exclusivity contributes to its premium pricing. However, this beauty comes with a caveat: maintenance. As mentioned, many natural stones are porous, meaning they can absorb liquids, leading to stains if spills aren’t cleaned up promptly. Marble, in particular, is susceptible to etching from acidic substances like lemon juice or vinegar, leaving dull marks on its polished surface. While professional cleaning and regular sealing can mitigate these issues, they represent an ongoing cost and a commitment to upkeep. For a homeowner who values pristine surfaces with minimal fuss, the long-term maintenance costs of certain natural stones might outweigh their initial aesthetic appeal. The cost of professional cleaning, specialized stone care products, and the potential need for re-polishing or re-sealing can add up over the lifespan of the installation.

Repairing natural stone can also be a more complex and expensive undertaking. Chips or cracks, especially in delicate stones like marble or certain types of granite, might require specialized techniques and materials for repair, often involving color-matching fillers and meticulous polishing to blend the repair seamlessly. In some cases, if a significant flaw or damage occurs to an entire slab, replacement might be the only option, incurring the full cost of a new slab and installation. This unpredictability in long-term maintenance and repair can be a significant factor when comparing the overall expense of natural versus engineered stone.

Engineered stone, particularly quartz, shines brightly in the realm of low maintenance. Its non-porous nature means it’s highly resistant to stains and doesn’t require regular sealing. Cleaning is typically as simple as wiping down with soap and water. This significantly reduces the ongoing costs associated with upkeep. The durability of engineered stone is another major advantage. Its hardness makes it resistant to scratches and chips, meaning it can withstand the rigors of daily use in busy kitchens and bathrooms without showing significant wear and tear. This resilience translates into a longer lifespan with fewer repair needs.

When it comes to repairs for engineered stone, minor chips or cracks can often be repaired by trained professionals, though the success and cost of these repairs can vary. The resin component of engineered stone can sometimes make repairs more visible than on natural stone, depending on the expertise of the technician and the complexity of the repair. However, the overall likelihood of needing such repairs is generally lower due to its superior durability. The consistency of engineered stone also means that if a section needs to be replaced, matching the original material is usually straightforward, avoiding the unique slab selection process that can complicate natural stone replacements.

The market positioning of engineered stone often places it in a sweet spot, offering a premium look and feel at a more accessible price point than many high-end natural stones. While basic granite or marble might be comparable in price to mid-range quartz, the higher tiers of natural stone, with their exotic colors and intricate patterns, often far exceed the cost of even the most sophisticated engineered options. This makes engineered stone a particularly attractive choice for those seeking to achieve a luxurious aesthetic without breaking the bank. It offers a tangible way to elevate a space, making high-end design more attainable.

However, it’s crucial to acknowledge that the category of “engineered stone” is broad. Different manufacturers and different formulations will have varying price points. Some higher-end engineered materials, perhaps those with unique proprietary resins or complex, multi-layered veining patterns that closely mimic rare natural stones, can indeed command prices comparable to or even exceeding mid-range natural stones. Likewise, the “cost” isn’t solely about the price per square foot. It’s also about the overall project budget. A simpler kitchen renovation might accommodate the cost of a high-quality engineered stone, while a more extensive project with extensive cabinetry, appliances, and other finishes might lead designers to opt for a more budget-friendly natural stone to allocate resources elsewhere.

The installation process for both materials is generally comparable in terms of labor intensity, with skilled professionals required for precise cutting, fitting, and finishing. However, the inherent consistency of engineered stone can sometimes streamline the installation process, leading to fewer on-site adjustments or unforeseen complications compared to working with the unique characteristics of natural stone slabs. This potential for a smoother installation can, in some instances, translate to slightly lower labor costs.

Ultimately, the question of “人造石和天然石材哪个贵?” doesn’t have a single, definitive answer. It’s a dynamic interplay of material choice, rarity, manufacturing processes, ongoing maintenance, and individual aesthetic preferences. Natural stone offers an irreplaceable connection to the earth, a unique artistry that no two pieces can replicate. Engineered stone, conversely, provides a harmonious blend of aesthetic appeal, unparalleled durability, and predictable performance, often at a more accessible price point. The decision hinges on a careful evaluation of priorities: Is it the undeniable, singular beauty of nature you seek, or the consistent, resilient elegance born from innovation? Your answer will illuminate which stone, in your unique design narrative, represents the wiser, and perhaps more valuable, investment.