The allure of a perfectly smooth, seemingly endless surface in our homes is undeniable. Whether it’s a pristine kitchen island that begs to be the centerpiece of your culinary adventures, or a sleek bathroom vanity that elevates your daily routine, the material we choose for these high-traffic areas plays a starring role in both aesthetics and functionality. Two of the most popular contenders in this arena are acrylic and solid surface. At first glance, they might appear to be distant cousins, both offering that coveted seamless look and a spectrum of design possibilities. However, a closer inspection reveals a nuanced world of differences that can significantly impact their performance, appearance, and suitability for your specific needs.

Let’s begin by dissecting acrylic, often celebrated for its luminous quality and remarkable versatility. When we talk about “acrylic” in the context of surfacing, we’re generally referring to a type of solid, non-porous synthetic material composed of acrylic polymers and mineral fillers. Think of it as a sophisticated, engineered plastic that’s been meticulously crafted to mimic the appearance and feel of natural stone, but with a host of engineered advantages. One of the most striking characteristics of acrylic is its inherent translucence. This means that light can actually pass through it, creating a subtle, ethereal glow that can be particularly dramatic when illuminated from within. This property opens up a world of creative design opportunities, allowing for integrated lighting effects that can transform a space from functional to breathtaking. Imagine a bar top that softly radiates light, or a reception desk that exudes a welcoming warmth.

Beyond its luminous potential, acrylic boasts an exceptionally smooth and non-porous surface. This is a critical advantage for hygiene-conscious environments. Because it doesn’t have tiny pores to harbor bacteria or absorb liquids, spills like red wine, coffee, or juice simply bead up on the surface, making them incredibly easy to wipe away. This makes acrylic a fantastic choice for kitchens, bathrooms, and healthcare settings where cleanliness is paramount. The non-porous nature also means that staining is rarely an issue. Unlike some natural stones that require diligent sealing to ward off discoloration, acrylic remains remarkably resistant to stains.

Furthermore, acrylic is known for its thermoformability. This is a fancy way of saying it can be heated and bent into curves and shapes that would be impossible with traditional materials. This allows for truly custom designs, from seamlessly integrated sinks and backsplashes that flow into the countertop, to intricate, sculptural elements. The fabrication process for acrylic often involves gluing pieces together with a special adhesive that chemically bonds the material, creating invisible seams. When done by skilled fabricators, these seams are virtually undetectable, contributing to that highly sought-after monolithic appearance.

However, like any material, acrylic has its considerations. While it’s durable, it can be susceptible to scratching. Its relatively softer composition means that sharp objects or abrasive cleaning pads can leave marks. The good news is that minor scratches can often be buffed out and repaired, especially by professionals. For everyday care, using a soft cloth and mild detergent is usually sufficient. It’s also important to be mindful of extreme heat. While acrylic can withstand typical kitchen heat, placing very hot pots or pans directly on the surface without a trivet can cause damage.

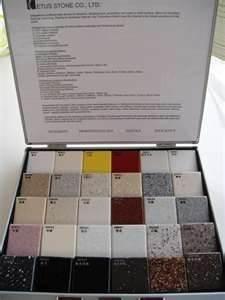

The range of colors and patterns available in acrylic is extensive. From solid, vibrant hues to realistic imitations of granite, marble, and quartz, designers can find an acrylic to suit almost any aesthetic. The consistent nature of the manufacturing process ensures that the color and pattern you choose will be uniform across the entire slab, providing a predictable and reliable outcome for your project. This predictability is a significant advantage for larger installations where maintaining a consistent look is crucial.

In summary of the acrylic realm, we’re looking at a material that champions luminosity, hygiene, and design flexibility. It’s a modern material that offers a high-tech solution for those seeking a sleek, seamless, and easily maintained surface with the added bonus of potential for unique lighting integration. It’s the material that whispers of contemporary elegance and sophisticated innovation, making it a strong contender for any space that values both form and function, with a particular nod to the visual impact and effortless upkeep.

Now, let’s pivot to the other significant player in the world of contemporary surfacing: solid surface. Often confused with acrylic due to their shared seamless appearance and non-porous nature, solid surface materials are, in fact, a distinct category with their own unique set of characteristics and applications. While acrylic is predominantly made from acrylic polymers, solid surface is typically a composite material. It’s usually composed of a blend of acrylic polymers and/or polyester resins, combined with a significant amount of mineral fillers, most commonly aluminum trihydrate (ATH). This composition gives solid surface its own robust set of properties that set it apart.

One of the most defining features of solid surface is its remarkable durability and resilience. The combination of resins and mineral fillers creates a material that is significantly harder and more impact-resistant than pure acrylic. This makes it an excellent choice for areas that experience heavy use and potential for bumps and knocks, such as busy commercial kitchens, high-traffic retail environments, and family homes where durability is a top priority. While it can still be scratched, it generally holds up better to daily wear and tear compared to its acrylic counterpart.

Like acrylic, solid surface is also non-porous. This is a crucial shared benefit, meaning it resists stains, bacteria, and moisture just as effectively. This makes it an equally superb option for kitchens and bathrooms, offering a hygienic and easy-to-clean surface. The absence of pores means that spills are easily wiped away, and the material won’t absorb odors or harbor mold and mildew. This contributes to a healthier living environment and reduces the need for harsh chemical cleaners.

The fabrication process for solid surface is also similar to acrylic in its ability to create seamless joints. Adhesives are used to bond pieces together, resulting in nearly invisible seams. This allows for large, continuous surfaces without unsightly grout lines or breaks, contributing to that sleek, modern aesthetic. Furthermore, solid surface can be thermoformed, though typically to a lesser degree and with larger radii compared to pure acrylic. This still allows for some degree of curvature and custom shaping, though intricate, tightly formed shapes might be more easily achieved with acrylic.

When it comes to repairs, solid surface generally performs very well. Minor scratches and chips can often be sanded out and polished, restoring the surface to its original condition. For deeper damage, professional repair is usually recommended, and the results are often quite impressive, making the material seem as good as new. This repairability is a significant factor in the longevity and cost-effectiveness of solid surface installations.

The aesthetic range of solid surface is vast, offering a wide array of colors, patterns, and textures. While it can mimic the look of natural stone, it also excels in offering unique, contemporary designs that may not be possible with natural materials. From subtle, mottled effects to bold, graphic patterns, solid surface provides designers with immense creative freedom. The consistency of manufacturing ensures that the color and pattern will be uniform throughout the slab, offering a predictable and reliable outcome for large projects.

So, what’s the fundamental difference? While both materials offer seamlessness and non-porosity, the core distinction lies in their composition and, consequently, their performance characteristics. Acrylic leans towards luminosity and extreme formability, making it ideal for design-forward applications and situations where internal lighting is a feature. Solid surface, on the other hand, emphasizes robust durability and impact resistance due to its higher mineral content. It’s the workhorse of the seamless surfacing world, offering a slightly tougher, more resilient option for demanding environments.

Choosing between acrylic and solid surface often comes down to prioritizing specific attributes. If you’re drawn to the idea of a surface that glows, or if you envision complex, flowing shapes, acrylic might be your go-to. If your primary concern is maximum durability, resistance to impact, and a proven track record in high-traffic areas, solid surface often takes the lead. Both materials represent a significant step up from traditional surfacing options, offering a blend of beauty, hygiene, and modern design that continues to shape the way we envision our living and working spaces. Understanding these nuances is key to selecting the material that not only looks stunning but also performs optimally for years to come.