The allure of a perfectly crafted surface—be it for a bustling kitchen island, a serene bathroom vanity, or a sleek reception desk—is undeniable. In the realm of modern interior design, two materials consistently vie for attention, each promising beauty, durability, and a touch of sophistication: acrylic and solid surface. While they often share the stage, particularly in their ability to create seamless, integrated designs, their fundamental compositions and inherent properties create a luminous divide, a subtle yet significant difference that can profoundly impact your project’s outcome. Understanding this divide isn’t just about aesthetics; it’s about making a choice that aligns with your functional needs, aesthetic aspirations, and long-term investment.

Let’s begin by demystifying the nature of acrylic. Often referred to by brand names like Corian (though Corian is technically a solid surface, the term has become somewhat generalized in everyday conversation), acrylic solid surface is a composite material. Its primary ingredients are mineral fillers, primarily aluminum trihydrate (ATH), derived from bauxite ore, and acrylic polymers. This blend is then cast into sheets or molded into specific shapes. The magic of acrylic lies in its inherent non-porosity and its remarkable homogeneity. The color and pattern are present throughout the entire thickness of the material, meaning that scratches or minor damage can often be repaired through sanding and polishing, restoring the surface to its original glory. This seamless repairability is a significant draw for many applications, especially in high-traffic areas or environments where hygiene is paramount, such as healthcare facilities or laboratories.

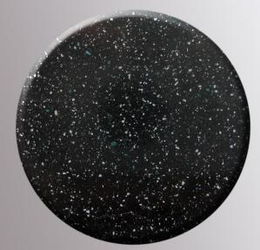

The visual versatility of acrylic is another key selling point. It can be manufactured in an astonishing array of colors, patterns, and textures, from the subtle elegance of faux granite and marble to vibrant, bold hues that make a statement. Furthermore, acrylic’s unique properties allow for thermoforming. This means that under controlled heat, sheets of acrylic can be bent, curved, and shaped into organic, fluid forms that are impossible to achieve with many other countertop materials like natural stone or quartz. Imagine a waterfall edge that flows effortlessly down the side of an island, or a freestanding reception desk with sweeping, sculptural curves. This design freedom opens up a universe of creative possibilities, allowing architects and designers to push the boundaries of conventional form.

The integration of sinks and backsplashes is another area where acrylic truly shines. Because the material is non-porous and can be seamlessly joined with itself, sinks can be integrated directly into the countertop, creating a smooth, continuous surface with no grout lines or visible seams. This not only enhances the aesthetic appeal by providing a clean, streamlined look but also significantly simplifies cleaning and maintenance. Water and grime have nowhere to hide, making it an exceptionally hygienic choice. This seamless integration extends to backsplashes, which can be coved up the wall, again eliminating those troublesome crevices where dirt and bacteria can accumulate. The result is a surface that is not only beautiful but also exceptionally practical and easy to keep pristine.

However, it’s crucial to acknowledge that while acrylic boasts impressive durability, it does have its limitations. Its relative softness compared to materials like quartz means it can be more susceptible to scratching from sharp objects or abrasive cleaning pads. While these scratches can often be buffed out, it requires a conscious effort and understanding of the material’s properties. Similarly, prolonged exposure to high heat can cause discoloration or even damage. Therefore, while a hot pot might be placed on a solid surface for a brief moment, using trivets is always recommended to preserve the integrity and beauty of an acrylic surface. This is a trade-off that many are willing to make for the design flexibility and seamless aesthetics it offers.

The manufacturing process of acrylic solid surface is also noteworthy. It involves a precise mixing of resins and fillers, followed by casting and curing. This controlled environment ensures a consistent product with predictable properties. The ability to produce large sheets with minimal variation means that projects requiring extensive countertop areas can be fabricated with a high degree of uniformity. The fabrication process itself is also relatively straightforward for skilled craftspeople. Cutting, routing, and joining acrylic can be done with standard woodworking tools, and the seamless joints are achieved through specialized adhesives that cure to become as strong and durable as the surrounding material. This ease of fabrication can sometimes translate to more competitive pricing compared to other high-end surfacing materials, making it an attractive option for a wide range of projects. In essence, acrylic offers a compelling blend of design potential, hygienic benefits, and a relatively accessible entry point into the world of premium surfacing.

Transitioning from the inherent qualities of acrylic, we now turn our attention to its counterpart, solid surface. While the terms are often used interchangeably in casual conversation, and there’s indeed overlap in their composition, it’s important to delineate the specific characteristics that define solid surface as a distinct category. At its core, solid surface is a man-made material composed of a polymer resin binder and mineral fillers. The most common type of resin used is polyester, though acrylic resins are also employed, leading to the confusion. When acrylic resins are the primary binder, the material is more accurately termed “acrylic solid surface,” as discussed previously. However, when polyester resins are dominant, or when a blend of resins is used, we generally refer to it as “solid surface.” The mineral fillers are typically aluminum trihydrate (ATH), which provides fire retardant properties and contributes to the material’s density and feel.

The key differentiator, in many instances, lies in the formulation and the resulting performance characteristics. Solid surface materials, particularly those with a higher proportion of mineral fillers and robust resin systems, can exhibit greater hardness and scratch resistance compared to some pure acrylic formulations. This enhanced durability makes them a robust choice for applications where daily wear and tear are a significant concern. While both materials are non-porous, the surface density and composition can influence their resistance to staining and etching from common household acids or chemicals. The quality and specific manufacturing process of a solid surface product will ultimately dictate its performance in these areas.

Aesthetically, solid surface offers a broad spectrum of design possibilities, mirroring acrylic in its ability to be manufactured in a vast array of colors, patterns, and finishes. From sophisticated neutrals that evoke natural stone to bold, contemporary hues, there’s a solid surface option to complement virtually any design scheme. The ability to achieve seamless integration of sinks and backsplashes remains a hallmark of solid surface, just as it is with acrylic. This seamlessness is born from the material’s inherent non-porosity and its capacity for being expertly joined with invisible seams. This creates a clean, hygienic, and visually uninterrupted surface that is highly sought after in both residential and commercial settings. The uniform color and pattern throughout the material also mean that minor scuffs and scratches can be repaired through sanding and buffing, restoring the surface’s original appearance.

However, the thermoforming capabilities of solid surface, while present, can be more limited in scope and radius compared to pure acrylic solid surface. While intricate curves and shapes are achievable, extremely tight bends or complex organic forms might be more challenging or require specific product formulations and expert fabrication. This is not to say that solid surface lacks design flexibility; rather, it’s a subtle nuance in its inherent properties that can influence the degree of sculptural freedom available. For most standard applications, including coved backsplashes and integrated sinks, solid surface excels.

When considering the application of heat, solid surface materials, like acrylics, generally benefit from the use of trivets or hot pads. While some formulations may offer slightly better heat resistance, it’s always prudent to avoid direct contact with extremely hot items to prevent thermal shock or discoloration. This is a universal consideration for most composite countertop materials, ensuring their longevity and pristine appearance.

The fabrication of solid surface involves cutting, routing, and joining the sheets using specialized adhesives that cure to create incredibly strong and seamless bonds. Skilled fabricators are essential for achieving the flawless integrated sinks, backsplashes, and any custom design elements. The non-porous nature of the material means that it’s inherently resistant to mold, mildew, and bacteria, making it an excellent choice for kitchens, bathrooms, healthcare environments, and food service areas where hygiene is a top priority. The ease of cleaning and the ability to sanitize surfaces without concern for porous absorption contribute significantly to its appeal in these demanding settings.

In conclusion, both acrylic and solid surface offer compelling advantages for a wide range of applications. Acrylic, with its superior thermoforming capabilities and often a slightly softer feel, excels in designs that embrace complex curves and organic shapes, while still providing exceptional hygiene and seamless integration. Solid surface, often characterized by a greater emphasis on hardness and scratch resistance, presents a robust and durable option that also delivers on aesthetics and seamless functionality. The choice between them often hinges on the specific demands of the project: the desired level of design complexity, the anticipated wear and tear, and the overall budget. Ultimately, both materials represent a sophisticated approach to surface design, offering beauty, durability, and a commitment to hygienic living.