The world of interior design and architectural marvels often feels like a realm of pure artistry, where spaces are transformed into breathtaking experiences. Yet, beneath the surface of stunning aesthetics lies a foundation of material science and manufacturing prowess. One material that has quietly revolutionized how we conceive of surfaces is acrylic solid surface. It’s the silent partner in countless kitchens, bathrooms, commercial spaces, and even artistic installations, lending its seamless beauty, durability, and incredible versatility to environments that inspire and function. But have you ever stopped to wonder where this magical material comes from? Who are the unseen architects that bring these elegant, seemingly endless planes of color and texture into existence? The answer, quite simply, lies with acrylic solid surface manufacturers.

These manufacturers are more than just factories churning out sheets of material. They are hubs of innovation, where chemistry meets craftsmanship, and where raw polymers are transformed into a canvas for creativity. The journey from basic acrylic resins and mineral fillers to the polished, ready-to-install slabs of solid surface is a complex and fascinating one, driven by a deep understanding of material properties and a commitment to quality. At its core, acrylic solid surface is a composite material, a carefully balanced blend designed to offer the best of both worlds: the visual appeal of natural stone with the practical advantages of a non-porous, highly adaptable synthetic. The “acrylic” in its name refers to the polymethyl methacrylate (PMMA) resin, a clear, strong thermoplastic that acts as the binder. This is meticulously mixed with mineral hydrates, primarily alumina trihydrate (ATH), which is derived from bauxite ore. Pigments are then added to achieve an astonishing spectrum of colors, from subtle earth tones and sophisticated grays to vibrant hues and intricate veining patterns that mimic natural stone with uncanny accuracy.

The manufacturing process itself is a marvel of modern engineering. It typically involves a process of casting or extrusion, where the homogenized mixture is poured into molds or extruded through dies. This is followed by a curing phase, where the material solidifies and gains its structural integrity. The resulting sheets, or sometimes custom-molded shapes, are then subjected to a series of finishing processes. This includes precise cutting, sanding, and polishing to achieve the desired surface finish – whether it’s a matte, semi-gloss, or high-gloss sheen. The result is a material that is not only aesthetically pleasing but also remarkably functional. Unlike natural stone, acrylic solid surface is non-porous, meaning it doesn’t absorb liquids, which makes it exceptionally resistant to stains, mold, and mildew. This inherent hygiene makes it an ideal choice for applications where cleanliness is paramount, such as healthcare facilities, laboratories, and, of course, kitchens and bathrooms.

Furthermore, the adaptability of acrylic solid surface is a key differentiator. It can be thermoformed – heated and bent into curves and complex shapes – allowing designers to create seamless, flowing designs that are impossible with traditional materials like granite or quartz. This thermoforming capability means that countertops can have integrated sinks, coved backsplashes that eliminate grout lines, and even furniture with organic, sculpted forms. The ability to achieve seamless joints is another significant advantage. When pieces of acrylic solid surface are joined using specialized adhesives that are color-matched, the seams become virtually invisible. This creates a monolithic, unbroken appearance that enhances both the aesthetic appeal and the hygienic properties of the surface, as there are no crevices for dirt and bacteria to accumulate.

The role of the acrylic solid surface manufacturer extends beyond simply producing the raw material. Many leading manufacturers also offer fabrication services or work closely with a network of certified fabricators. These professionals possess the specialized skills and equipment to cut, shape, and install the solid surface according to precise design specifications. This integrated approach ensures that the material’s potential is fully realized, from the initial design concept to the final installed product. It’s this synergy between material science, manufacturing expertise, and skilled fabrication that makes acrylic solid surface such a compelling choice for a wide range of applications. The sheer diversity of what can be achieved with this material is truly staggering. Think of reception desks in corporate lobbies that greet visitors with smooth, elegant curves; laboratory benchtops that withstand harsh chemicals and frequent sterilization; or even artistic sculptures that seem to defy gravity. Each of these applications owes its existence to the foundational properties of acrylic solid surface, meticulously engineered and brought to life by dedicated manufacturers. As we move into the second part, we’ll explore what makes a manufacturer truly exceptional and the impact they have on the world of design.

As we delve deeper into the world of acrylic solid surface, it becomes clear that the true magic lies not just in the material itself, but in the expertise and vision of the acrylic solid surface manufacturers who bring it to life. Choosing the right manufacturer is akin to selecting the right artist for a masterpiece; it’s about finding a partner who understands the nuances of the material, possesses a commitment to quality, and can translate creative visions into tangible realities. What then, sets a leading acrylic solid surface manufacturer apart from the rest? It boils down to a confluence of factors, each contributing to the overall excellence of their products and services.

Foremost among these is an unwavering commitment to quality control. The manufacturing process for acrylic solid surface requires precise formulations and stringent control over temperatures, pressures, and curing times. A reputable manufacturer will have robust quality assurance protocols in place at every stage of production, from the sourcing of raw materials to the final inspection of the finished sheets. This meticulous attention to detail ensures consistency in color, texture, and physical properties, guaranteeing that the material performs as expected and maintains its aesthetic integrity over time. This is crucial for designers and clients who rely on predictable and reliable performance for their projects.

Innovation is another hallmark of a superior acrylic solid surface manufacturer. The field is not static; advancements in polymer chemistry, pigment technology, and manufacturing techniques are constantly pushing the boundaries of what’s possible. Leading manufacturers invest in research and development to create new colors, textures, and performance characteristics. This might include developing materials with enhanced UV resistance for outdoor applications, improved scratch resistance for high-traffic areas, or even incorporating antimicrobial properties for specialized environments. Their willingness to experiment and pioneer new solutions ensures that designers have an ever-expanding palette of options to work with, allowing for more creative and functional outcomes.

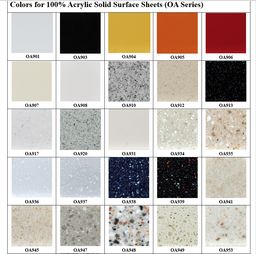

The breadth and depth of their product offerings are also significant indicators. A comprehensive range of colors, patterns, and finishes allows designers the freedom to select the perfect aesthetic for any project, without compromise. Beyond standard sheets, some manufacturers excel in offering custom solutions, working collaboratively with clients to develop unique color matches or specialized formulations to meet specific project requirements. This ability to tailor the material to individual needs is a testament to their technical expertise and customer-centric approach.

Furthermore, the support and services provided by a manufacturer play a pivotal role. This includes providing detailed technical specifications, offering design assistance, and ensuring timely delivery. A manufacturer that also has strong relationships with certified fabricators, or offers in-house fabrication services, can streamline the entire project lifecycle. This seamless integration from material supply to final installation minimizes potential issues, reduces lead times, and ensures that the complex fabrication processes, like thermoforming and seamless joining, are executed to the highest standards. The availability of comprehensive training and support for fabricators is also key, as it empowers them to fully leverage the capabilities of the material.

The reputation and track record of a manufacturer are invaluable. Years of successful projects, positive testimonials, and industry recognition speak volumes about their reliability and the quality of their products. Looking for manufacturers who have a history of working on significant architectural and interior design projects can provide confidence in their capabilities. It’s about trusting a partner who has consistently delivered excellence and understands the demands of professional design and construction.

Ultimately, acrylic solid surface manufacturers are more than just suppliers; they are collaborators in the design process. They provide the foundational elements that allow architects, interior designers, and builders to translate their visions into reality. By understanding the properties of acrylic solid surface and the crucial role of its creators, we can better appreciate the sophistication and artistry that goes into shaping the spaces we inhabit. From the sleek lines of a modern kitchen countertop to the innovative curves of a public art installation, the influence of these manufacturers is pervasive, quietly shaping the beauty and functionality of our built environment, one seamless surface at a time. Their dedication to material science, manufacturing excellence, and customer satisfaction makes them indispensable partners in the pursuit of exceptional design.