The Unseen Weight: Decoding the Mystery of Artificial Stone Kitchen Countertop Density

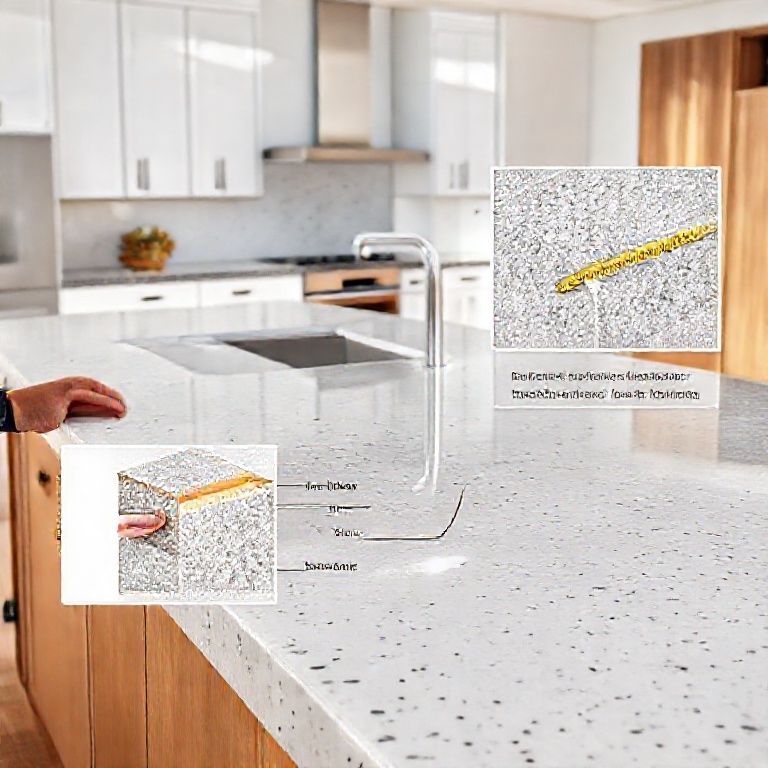

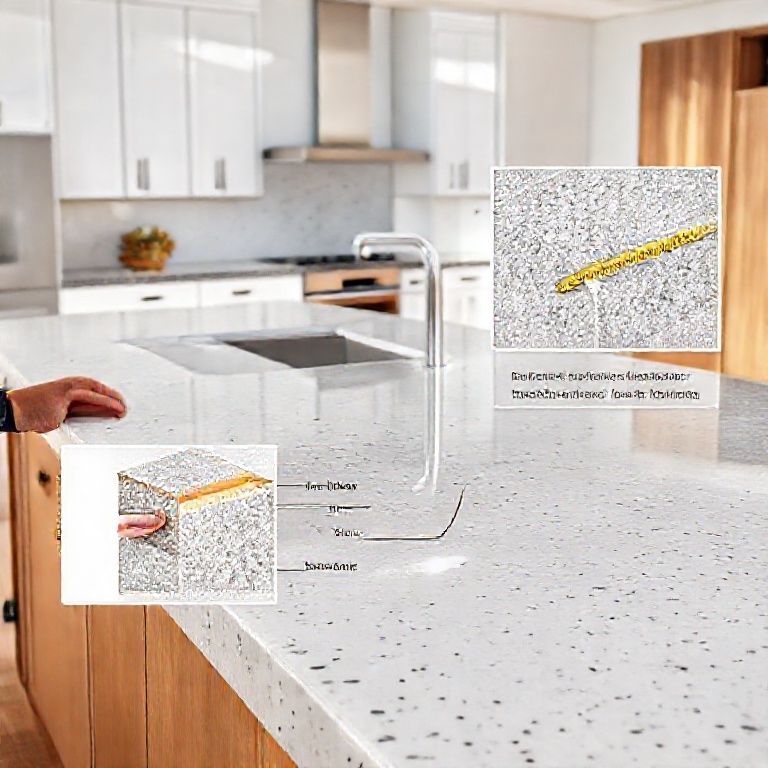

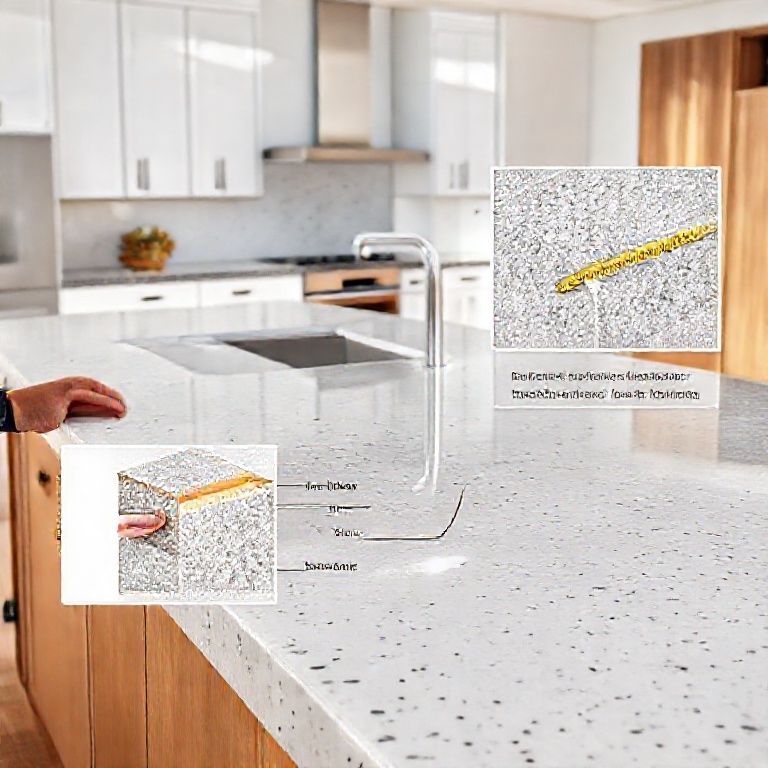

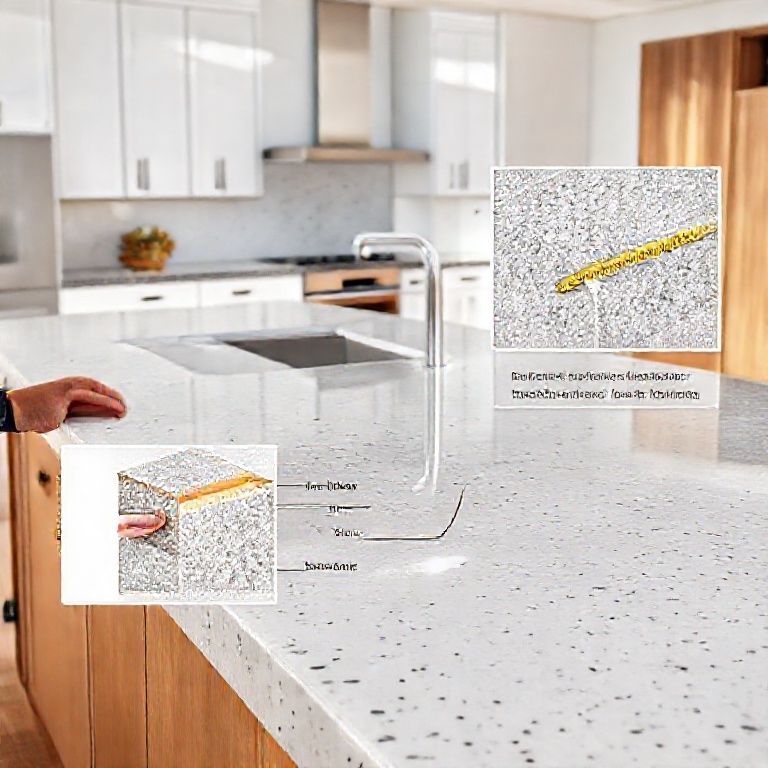

The heart of any home often beats strongest in the kitchen. It’s where culinary dreams are born, where families gather, and where the day’s stories are shared over steaming mugs. And at the center of this vibrant hub often lies the kitchen countertop – a surface that’s not just functional but also a significant aesthetic statement. When we talk about artificial stone countertops, particularly in contexts where dimensions like “2.4 meters” are mentioned, a curious question often arises: how much does it weigh? This isn’t just idle curiosity; understanding the weight of your countertop material is crucial for a myriad of reasons, from installation logistics to understanding the inherent quality and density of the material itself.

Let’s embark on a journey to demystify this. The phrase “2.4 meters” typically refers to the length of a standard countertop slab. However, weight isn’t solely determined by length. It’s a product of three-dimensional volume and material density. Imagine two pieces of wood, both the same length. One might be a thin plank, while the other is a thick beam. Clearly, the beam will be considerably heavier. Similarly, with artificial stone, the thickness and the specific composition of the material play equally vital roles in its overall heft.

Artificial stone, often referred to as engineered stone or quartz surfaces, is a marvel of modern material science. Unlike natural granite or marble, which are quarried directly from the earth, artificial stone is manufactured. The primary ingredient is natural quartz crystals, which typically make up 90-95% of the material. These quartz particles are then bound together with a polymer resin and pigments are added to achieve a vast array of colors and patterns. This manufacturing process offers several advantages, including consistency in appearance, enhanced durability, and crucially for our discussion, a predictable density.

So, what does this mean for the weight of a 2.4-meter slab? We need to consider the standard thickness of these countertops. Common thicknesses range from 2 centimeters (approximately 0.79 inches) to 3 centimeters (approximately 1.18 inches). Thicker slabs naturally weigh more. Now, let’s talk density. The density of engineered quartz countertops typically falls within a range of 2.5 to 2.7 grams per cubic centimeter (g/cm³), or approximately 2500 to 2700 kilograms per cubic meter (kg/m³). This is comparable to, and often denser than, many natural stones like granite.

To put this into perspective, let’s do some rough calculations. Assume a standard thickness of 2 centimeters (0.02 meters) and a length of 2.4 meters. We also need to consider the width. A typical kitchen countertop width is around 60-65 centimeters (0.6-0.65 meters). Let’s use an average width of 0.625 meters.

The volume of our hypothetical 2.4-meter slab would be: Volume = Length × Width × Thickness Volume = 2.4 m × 0.625 m × 0.02 m Volume = 0.03 cubic meters (m³)

Now, using our density range, we can estimate the weight: Minimum Weight = Volume × Minimum Density Minimum Weight = 0.03 m³ × 2500 kg/m³ Minimum Weight = 75 kilograms

Maximum Weight = Volume × Maximum Density Maximum Weight = 0.03 m³ × 2700 kg/m³ Maximum Weight = 81 kilograms

So, a standard 2.4-meter long artificial stone countertop, typically 2 cm thick and 62.5 cm wide, would weigh approximately between 75 and 81 kilograms (around 165 to 179 pounds). This is a substantial weight, comparable to a fully grown adult!

If we consider a thicker slab, say 3 centimeters (0.03 meters) with the same length and width: Volume = 2.4 m × 0.625 m × 0.03 m Volume = 0.045 cubic meters (m³)

Minimum Weight (3 cm thick) = 0.045 m³ × 2500 kg/m³ = 112.5 kilograms Maximum Weight (3 cm thick) = 0.045 m³ × 2700 kg/m³ = 121.5 kilograms

In this case, a 3 cm thick slab would weigh between 112.5 and 121.5 kilograms (around 248 to 268 pounds). This significantly heavier weight has direct implications for installation.

The sheer weight of these countertops is a critical factor that installers must contend with. Transporting these heavy slabs from the supplier to the home, and then maneuvering them into place on the kitchen cabinets, requires specialized equipment and skilled labor. Dollies, lifting straps, and sometimes even cranes might be necessary, especially for larger or thicker pieces. The supporting structure of the cabinets also needs to be robust enough to bear this considerable load. Fortunately, engineered stone is known for its strength, so the material itself is usually capable of supporting its own weight and the demands of kitchen use, provided the base cabinets are properly constructed and installed.

Beyond the practicalities of installation and structural support, the weight of an artificial stone countertop is also an indicator of its quality and composition. Higher density generally correlates with a more tightly packed material, fewer voids, and a stronger, more durable surface. This translates to better resistance against stains, scratches, and heat. When you’re investing in a kitchen countertop, understanding its weight is a subtle yet important way to gauge the substance and reliability of the material you’re bringing into your home. It’s a tangible aspect of a product that promises to be a lasting fixture in your daily life, contributing not just to the beauty but also to the structural integrity of your cherished kitchen space.

Continuing our exploration into the weighty subject of artificial stone kitchen countertops, we’ve established that a 2.4-meter slab carries a significant amount of heft, largely dictated by its thickness and material density. But what else contributes to this, and how does this weight influence our design choices and the overall kitchen experience? Let’s delve deeper into the nuances that make up the mass of these sophisticated surfaces.

While the core composition of engineered stone is primarily quartz (90-95%), the remaining 5-10% comprises polymer resins and pigments. These binders are crucial. They are typically thermosetting polyester or epoxy resins that, when combined with quartz and subjected to a high-pressure, high-temperature process (often involving vibration and vacuum), create a solid, non-porous slab. The type and amount of resin used can subtly influence the density and therefore the weight. Higher resin content might lead to slightly lower density in some formulations, though the inherent density of quartz is the dominant factor. Pigments, while present in very small quantities, contribute negligibly to the overall weight.

The manufacturing process itself plays a significant role. Techniques like Breton technology, a leading method in quartz surface production, employ intense vibration and vacuum to consolidate the mixture, minimizing air voids. The more effectively these voids are eliminated, the denser and heavier the final product. This is why reputable manufacturers often achieve very consistent densities across their product lines, ensuring predictable weight and superior performance characteristics.

It’s also worth noting that not all “artificial stones” are created equal. While engineered quartz is the most prevalent type, other composite materials might fall under a similar umbrella. For instance, some products might incorporate a higher percentage of fillers or different types of resins, potentially altering their density and weight. However, for the high-quality, well-known brands of quartz countertops, the density figures we’ve discussed are generally reliable.

The implication of this weight extends far beyond the initial installation. A denser, heavier countertop often translates to superior performance in the kitchen. Its non-porous nature, a direct result of its tightly packed structure, means it resists stains from coffee, wine, and oil far better than porous materials like unsealed natural stone or laminate. This resistance to liquids also makes it highly hygienic, as bacteria and mold have no easy way to penetrate the surface.

Furthermore, the density contributes to its remarkable durability. Engineered stone is exceptionally hard and resistant to scratching and chipping. While no countertop is indestructible, a denser material typically offers a more robust barrier against the daily wear and tear of a busy kitchen – from chopping vegetables (though a cutting board is always recommended!) to the accidental slide of a heavy pot. Its resistance to heat is also notable; while extreme, direct heat can potentially damage the resin binders, the dense quartz structure itself can withstand moderate temperatures, making it a forgiving surface for placing warm dishes.

Considering the weight also informs decisions about kitchen design and cabinetry. For lighter-duty cabinets or islands that might not have a robust underlying structure, opting for a thinner (e.g., 2 cm) or slightly less dense engineered stone might be prudent. Conversely, if you’re designing a grand kitchen with substantial cabinetry, a thicker, more imposing 3 cm slab can enhance the sense of luxury and stability, further solidifying the countertop as a central, enduring element.

The visual aspect, too, is subtly linked to the material’s density. The consistent patterns and the depth of color achievable in engineered stone are facilitated by the controlled manufacturing process that results in these dense slabs. This consistency allows designers to plan layouts with seamless joins and predictable aesthetics, knowing that the material’s physical properties are reliable.

In essence, when we ask “how much does a 2.4-meter artificial stone countertop weigh?”, we’re not just inquiring about a number. We’re probing the material’s composition, its manufacturing integrity, and its likely performance characteristics. The weight is a tangible indicator of the quality and durability you can expect. It’s a silent promise of a surface that can withstand the rigors of daily life while maintaining its beauty. From the skilled hands that lift and place it to the sturdy cabinets that support it, the weight of your artificial stone countertop is an integral part of its story, contributing to the overall functionality, longevity, and aesthetic appeal of your kitchen. It’s a testament to the fusion of natural elements and human ingenuity, resulting in a material that’s as strong and reliable as it is beautiful.