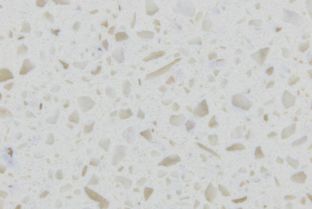

The gleam of artificial marble has become an almost ubiquitous presence in contemporary interior design. From the sleek countertops of minimalist kitchens to the elegant vanity tops in luxurious bathrooms, this engineered material offers a compelling blend of aesthetic appeal and practical performance. Its consistent patterns, vibrant colors, and remarkable durability have made it a darling of homeowners and designers alike, promising a touch of sophistication without the inherent variabilities of natural stone. But as we invite these luminous surfaces into our living spaces, a natural question arises: what lies beneath the polished veneer? Specifically, concerns often surface regarding the presence of radiation and the emission of formaldehyde, two invisible factors that can impact the health and well-being of those who inhabit these spaces.

Let’s first address the specter of radiation. The term itself can conjure images of scientific experiments or perhaps more sinister, unseen dangers. When it comes to building materials, the concern often stems from naturally occurring radioactive elements like uranium, thorium, and potassium, which can be present in varying concentrations within rocks and minerals. These elements decay over time, emitting alpha, beta, and gamma radiation. While natural stones like granite can sometimes contain trace amounts of these elements, leading to very low levels of radiation, artificial marble, in most cases, presents a significantly different profile.

Artificial marble, often referred to as engineered stone or quartz surfaces, is primarily composed of natural quartz crystals (around 90-95%), bound together by polymer resins and pigments. The raw materials used in its production are meticulously selected and processed. The natural quartz itself, while technically a mineral, is generally considered to be extremely low in radioactive isotopes compared to some other naturally occurring rocks. The manufacturing process involves crushing the quartz, mixing it with resins and pigments, and then compressing and heating it under vacuum. This intensive process further reduces the likelihood of concentrated pockets of radioactive elements forming within the final product.

Regulatory bodies and scientific studies have consistently found that the levels of natural radioactivity in most artificial marble products are negligible, often below the detection limits of standard testing equipment and well within safe environmental standards. Reputable manufacturers adhere to strict quality control measures and often conduct their own testing to ensure their products meet international safety benchmarks. The International Agency for Research on Cancer (IARC) has classified granite as a Group 1 carcinogen (carcinogenic to humans) when inhaled as dust, but this is primarily related to occupational exposure to silica dust during cutting and processing, not to the radiation emitted from installed surfaces. For installed artificial marble, the radiation levels are so low that they pose no discernible health risk to occupants. Think of it this way: the background radiation we are all exposed to from the sun, cosmic rays, and even the earth beneath our feet is generally far higher than what a typical artificial marble surface might emit.

However, it’s always prudent to be an informed consumer. If you have specific concerns, especially for larger installations or if you are particularly sensitive to environmental factors, you can inquire with manufacturers about their specific product testing and certifications related to radioactivity. Many manufacturers are transparent about their materials and processes and can provide data or documentation. The key takeaway is that the fears surrounding radiation from artificial marble are largely unfounded for the vast majority of products available on the market. The beauty and functionality of these surfaces are not typically compromised by any significant radiological concerns.

The second significant concern that often accompanies discussions about manufactured materials is the potential for the release of formaldehyde. Formaldehyde is a volatile organic compound (VOC) that can be found in a wide range of household products, from pressed wood furniture to certain adhesives and paints. It is known to be an irritant to the eyes, nose, and throat, and prolonged exposure to higher concentrations has been linked to more serious health issues. Therefore, understanding the formaldehyde content in artificial marble is crucial for creating a healthy indoor environment.

In the case of artificial marble, the primary binding agent is polymer resin, typically a polyester or acrylic resin. While resins themselves can contain trace amounts of unreacted monomers or other chemicals, the manufacturing process for high-quality artificial marble is designed to cure these resins thoroughly. This curing process chemically binds the components together, significantly minimizing the release of free formaldehyde. Reputable manufacturers prioritize using low-VOC or zero-VOC resins and implement stringent quality control to ensure minimal off-gassing. The finished product, once cured and installed, should have very low to negligible formaldehyde emissions.

The concern about formaldehyde is more pronounced with materials like medium-density fiberboard (MDF) or particleboard, where formaldehyde-based adhesives are commonly used, and these materials can off-gas over time, especially when new. Artificial marble, with its quartz and resin composition, falls into a different category. The resins used are engineered to create a durable, non-porous surface, and during the high-pressure, high-temperature manufacturing process, the resins are designed to fully polymerize, effectively locking in any volatile components.

To further address this, many countries have established regulations and standards for VOC emissions from building materials, including formaldehyde. Products that meet these standards, such as those with GREENGUARD or similar certifications, have been tested and verified to emit low levels of VOCs, ensuring they contribute minimally to indoor air pollution. When selecting artificial marble, looking for these certifications can provide an extra layer of reassurance. It signifies that the product has undergone independent testing and meets rigorous standards for indoor air quality.

The non-porous nature of artificial marble also plays a role in its overall health profile. Unlike natural stone which might absorb spills and harbor bacteria, artificial marble is highly resistant to stains and moisture. This makes it easier to clean and maintain, reducing the need for harsh cleaning chemicals that can themselves contribute to indoor air pollution. A simple wipe-down with mild soap and water is usually sufficient, promoting a healthier living environment in more ways than one.

Ultimately, the widespread adoption of artificial marble in homes and commercial spaces is a testament to its successful combination of aesthetic appeal, practical performance, and, importantly, a generally favorable safety profile. While it is always wise to approach any building material with an informed perspective, the concerns surrounding radiation and formaldehyde in modern, reputable artificial marble are largely addressed by the materials used and the manufacturing processes employed. The luminous allure of artificial marble can thus be enjoyed with a greater sense of peace of mind, knowing that its beauty does not come at the expense of your well-being.

Continuing our exploration into the world of artificial marble, we delve deeper into the nuances of its composition and manufacturing processes that contribute to its favorable safety profile, particularly concerning radiation and formaldehyde emissions. Understanding these aspects can empower consumers to make informed choices that align with their desire for both beautiful interiors and healthy living spaces. The journey from raw materials to a gleaming countertop involves sophisticated engineering, and it’s within this engineering that the answers to our safety queries often lie.

The primary component of artificial marble is ground natural quartz, which is a silicate mineral. Quartz is one of the most abundant minerals in the Earth’s crust. While all naturally occurring materials contain some level of naturally occurring radioactive material (NORM), the specific types and concentrations of radioactive isotopes within the quartz used for artificial marble are generally very low. Manufacturers source their quartz from deposits that are known to be of high purity and low radioactivity. This careful selection of raw materials is the first line of defense against any potential radiological concerns. The process of crushing and processing the quartz further homogenizes the material, dispersing any trace elements uniformly rather than allowing them to concentrate in specific areas. This ensures that the final product is consistently low in radioactivity.

The binder used in artificial marble production is typically a polymer resin, most commonly a polyester or an epoxy resin. These resins are engineered to be durable, strong, and resistant to stains and chemicals, which are key attributes that make artificial marble so desirable. The critical factor in minimizing any potential off-gassing, including formaldehyde, lies in the polymerization and curing of these resins. The manufacturing process involves mixing the quartz aggregate with the resin and pigments, and then compressing and heating this mixture under vacuum. This process, known as vibrocompression, solidifies the material and cures the resins.

During the curing process, the liquid resin undergoes a chemical transformation, hardening and becoming an integral part of the solid slab. This polymerization process effectively locks in the molecular structure, significantly reducing the potential for volatile compounds, such as unreacted monomers or residual solvents, to escape into the air. High-quality manufacturers invest in advanced curing technologies and stringent quality control protocols to ensure that this polymerization is complete. This means that the resins are fully reacted and stable, leading to minimal to negligible emissions of formaldehyde and other VOCs from the finished product.

It is important to differentiate artificial marble from other composite materials where formaldehyde-based adhesives might be used, such as in some particleboard or MDF products. In those materials, formaldehyde can be released over time as the adhesives degrade or as residual formaldehyde escapes. Artificial marble, by its very nature and manufacturing process, avoids this issue. The resins used are designed to be inert once cured, forming a solid, stable matrix with the quartz.

The non-porous nature of artificial marble is another significant advantage from a health perspective. Unlike natural stone, which can have micro-pores that absorb liquids, bacteria, and odors, artificial marble is virtually impermeable. This makes it incredibly hygienic and easy to clean. A simple regimen of wiping down surfaces with mild soap and water is usually sufficient to maintain cleanliness. This ease of maintenance means that homeowners are less likely to resort to harsh, chemical-laden cleaning agents that can contribute to poor indoor air quality. The reduced need for strong disinfectants and cleaning sprays means fewer VOCs are introduced into the home environment through cleaning practices.

Furthermore, the aesthetic consistency of artificial marble means that consumers are less likely to encounter unexpected issues related to material composition. Natural stones can have variations in their mineral makeup, and while these variations contribute to their unique beauty, they can also, in rare cases, lead to differences in radioactivity or porosity. Artificial marble, due to its controlled manufacturing process, offers a predictable and uniform product.

For consumers who remain particularly concerned about indoor air quality, seeking out artificial marble products with relevant certifications can provide an additional layer of confidence. Certifications such as GREENGUARD, GREENGUARD Gold, or similar standards from other reputable organizations, indicate that the product has been tested for a wide range of chemical emissions, including formaldehyde and other VOCs, under real-world conditions. Products that achieve these certifications have demonstrated very low emission levels, contributing to healthier indoor environments. Manufacturers committed to sustainability and health often prominently display these certifications on their products and marketing materials.

The longevity and durability of artificial marble also contribute to a healthier home in the long run. Because it is resistant to chipping, scratching, and staining, it maintains its aesthetic appeal and functional integrity for many years. This reduces the need for premature replacement, which in turn minimizes the environmental impact associated with manufacturing and waste. A durable surface that doesn’t degrade or require frequent replacement indirectly supports a healthier living space by reducing the introduction of new materials and potential off-gassing over time.

In summary, the radiant beauty of artificial marble is not typically accompanied by significant concerns regarding radiation or formaldehyde emissions when choosing reputable brands and products. The careful selection of low-radioactivity quartz, the advanced curing of polymer resins, and the inherent non-porous and durable nature of the material all contribute to a safe and healthy surface for any home. By understanding the science behind its creation and looking for relevant certifications, consumers can confidently embrace artificial marble, allowing its luminous allure to enhance their living spaces without compromising their well-being. The peace of mind that comes from knowing your chosen materials are both beautiful and safe is, after all, a crucial element in creating a truly comfortable and healthy home.